Key Takeaways:

- “Motion waste” refers to unnecessary movements in warehouse operations, leading to reduced productivity and increased operational costs.

- The detrimental effects of motion waste range from longer putaway and picking times to increased employee absenteeism and turnover.

- Effective ways to eliminate motion waste include identifying its causes, developing standard operating procedures, improving warehouse layout, creating optimized putaway and pick paths, and implementing Single-Minute Exchange of Die (SMED).

- A Warehouse Management System (WMS) like Logiwa can significantly assist in optimizing processes to cut down motion waste.

- By reducing motion waste, warehouses can significantly enhance productivity, decrease labor costs, and improve overall service levels.

“Lean manufacturing” is a buzzword that gets thrown around a lot these days. But, very few managers actually take the time to learn the tenets of the “lean way.” Lean manufacturing is all about the systematic and deliberate minimization of waste, which can be defined as any activity that doesn’t add value for the customer.

In total, the lean manufacturing methodology identifies eight sources of waste:

- Defects waste

- Overproduction waste

- Waiting waste

- Unused talent waste

- Transportation waste

- Motion waste

- Inventory waste

- Extra-processing waste

In this article, we’re going to focus on motion waste: the silent killer of warehouse productivity:

BONUS: Before you read further, download our Warehouse Management Software Whitepaper to see how Logiwa uses real-time data to help you get up to 100% inventory accuracy and execute advanced fulfillment strategies like wave planning.

What is Motion Waste?

Motion waste refers to unnecessary movements within the warehouse. It can be as noticeable as walking across the entire warehouse unnecessarily or as seemingly insignificant as rotating a tool for use after plucking it from a box. Other examples include:

- Sorting through a pile of tools to find the right one

- Retrieving an item that fell on the floor

- Reaching across a workbench to grab a tool

- Regularly walking back and forth to use a piece of equipment

The lean methodology encourages warehouse managers to identify unnecessary movements – both large and small – and eliminate them. Even the tiniest unnecessary movements add up!

According to one McKinsey report, warehouses can save anywhere from 20 to 50% in warehousing and up to 40% in transportation by adopting lean techniques. Addressing and eliminating motion waste is a huge step in this approach.

One of the first documented examples of addressing motion waste – from before lean manufacturing or ergonomics even came on the scene – comes from the bricklaying world. At age 16, Frank Bunker Gilbreth observed bricklayers working and noticed that they all moved differently, some more efficiently than others.

After he’d moved up the ranks into a management position, he reduced the movements of bricklayers from 18 to 5 and introduced a number of improvements, including:

- Reducing the number of times workers bent over by creating adjustable scaffolding

- Inventing new work tools

- Refining the workflow and processes

What set Gilbreth apart from his peers was his focus on motion rather than time. His later business and research focused on finding the most optimal movements for completing a task.

It’s this focus on movement that informs today’s efforts in occupational health (ergonomics) and lean management (reducing motion waste).

The Detrimental Effects of Motion Waste

It may be tempting to put motion waste elimination on the back burner. When you have orders to fulfill, inventory to put away, and goods to pick, focusing on yet another continuous improvement effort seems like a distraction.

But, when you consider the detrimental effects of motion waste on your warehouse environment and your business’s bottom line, you’ll understand why it’s better to eliminate it sooner rather than later.

Reduced Productivity

Have you ever spent more time preparing to do something than actually doing it?

In a warehouse, there are all sorts of tiny tasks workers must perform before they get to the task at hand. They may need to sort through a box of tools to find the right one. They may find the right tool, but not the right size. They may need to use several pieces of equipment sequentially, but the layout of the warehouse forces them to walk back and forth several times per shift to access the right equipment.

All of these scenarios demonstrate how motion waste causes reduced productivity. You have people walking around unnecessarily trying to get a job done.

Longer Putaway and Picking Times

Too stressed out by putaway and picking to think about motion waste?

Well, consider how motion waste contributes to inefficient processes in both of those activities. If your team doesn’t have an optimized putaway process or optimized pick path algorithm, then they’re likely taking longer than they need to get the job done.

Both of these processes are labor intensive, and motion waste is all about the inefficient use of human resources. Eliminating motion waste and coming up with better strategies can lower your labor costs while also improving your service levels.

In other words: It’s something you should be prioritizing.

Increased Employee Absenteeism

One Survey of Occupational Injuries and Illnesses by the Bureau of Labor Statistics found that musculoskeletal disorders (MSDs) accounted for 29% of all workplace injuries that resulted in time away from work.

In a labor-intensive environment like a warehouse, a low absenteeism rate can be the difference between getting the job done and disappointing customers with late orders. Warehouse workers are at a particularly high risk for MSDs due to all of the lifting, bending, and other repetitive motions required to complete the job.

Eliminating motion waste and refining the standard ways to move within a warehouse can lead to better health outcomes among warehouse workers, reduced absenteeism, and higher productivity.

Higher Turnover

Warehouses are facing a labor shortage, which, in turn, has led to rising wages. Reducing motion waste can help you lower your turnover rate (e.g., keep your employees) while also getting more done with the employees you have.

Let’s take a look at the first outcome: keeping your workers. People don’t like inefficiency. When you’re a smart, hard-working person, coming to a job where management isn’t paying attention to the warehouse’s layout, efficiency, and processes has a demoralizing effect.

In fact, researchers have studied the effect of poor processes on workers. One study found that inefficient or useless tasks have a negative impact on workers’ mental health. It goes without saying that unhappy workers are unproductive workers. Moreover, they’re more likely to quit, which has a snowball effect:

- Lost workers reduces productivity

- Additional workload for remaining workers further reduces employee morale

- Additional cost to management to source, interview, and hire additional warehouse workers

- Additional cost to pay new workers the new market rate

By eliminating motion waste, you can keep workers happy, reduce turnover, and get more work done with the people you already have.

Better Warehouse Performance = Higher Profit Margins: Logiwa syncs accurate data across your entire interface so the inventory numbers you see on your dashboard are what your employees see on their devices. Learn how Logiwa uses real-time data to help you get up to 100% inventory accuracy and 2.5x shipments.

How To Eliminate Motion Waste In Your Warehouse

Eliminating motion waste is not a “one and done” proposition. Instead, it’s a continuous process that requires a review of your existing processes, buy-in from upper management and workers, and dedicated execution of your motion waste elimination strategy.

Identify the Causes of Motion Waste

It may not be entirely clear where the motion waste issues are. Perhaps it’s an issue only workers on the floor would notice, like sorting through several boxes to find the right tool. It may be something anyone walking through the warehouse would spot, like equipment used consecutively in a process being located on opposite ends of the warehouse.

The best way to identify motion waste is to gather workers from different areas of the warehouse and ask:

- Where do you notice yourself taking unnecessary steps to complete a task?

- What areas of the warehouse layout or warehouse organization would you change if you were in charge?

- Which changes do you think should take priority?

This consultation process will accomplish two things:

- Give you a realistic understanding of your warehouse processes

- Demonstrate to your workers that their input and experiences matter to management

Develop Standard Operating Procedures

While the solutions you implement will depend on your warehouse’s specific trouble areas, developing a set of standard operating procedures (SOPs) is a best practice that can help eliminate most types of motion waste.

- Identify and document the minimum number of steps required to complete a task

- Identify the materials needed to complete a specific task

- Schedule time and allocate human resources to the periodic organization and clean-up of equipment needed for each area

- Give representatives from your workforce the opportunity to contribute to, review, and revise the SOPs

Improving the Layout and Organization of Your Warehouse

Imagine a manufacturing process that consists of three consecutive steps, each with technology that must be used consecutively. If those pieces of equipment are located far apart from each other, workers take unnecessary steps every time they perform the process.

Solution: Move the equipment closer together.

In addition, if your workers need specific tools or materials for a certain process (e.g., boxes for packaging), move the materials section closer to the associated area.

What’s more, improving the layout of your warehouse isn’t just about moving pieces of equipment closer to each other. It’s also about how you position them. Let’s return to our example of a packaging station. It isn’t enough to simply move the boxes to be close to the packaging station. Take it one step further to reduce additional motion waste: If there’s a shelf full of differently sized boxes that your packers use, place the most frequently used type of box within arm’s reach and the less frequently used type of box on higher or lower shelves.

You should always be looking for ways to limit the amount of reaching and bending your employees need to do.

Depending on your warehouse’s budget and volume of work, you may be able to introduce automation to eliminate motion waste via conveyors or automated packaging systems.

Create Optimized Putaway and Pick Paths Using Your Warehouse Management System

Check out the various functionalities within your warehouse management system (WMS). Some systems help warehouses identify the optimal pick path for their employees. In essence, an optimized pick path means that when a worker picks an item, they’re directed to pick the nearest item, rather than the next item on their list. This saves time and labor while increasing productivity.

Implement Single-Minute Exchange of Die

Motion waste isn’t limited to the execution of a task. It also occurs during the changeover from one task to another. The concept of changeover – the switch from one product run to another – is mostly relevant for manufacturing facilities.

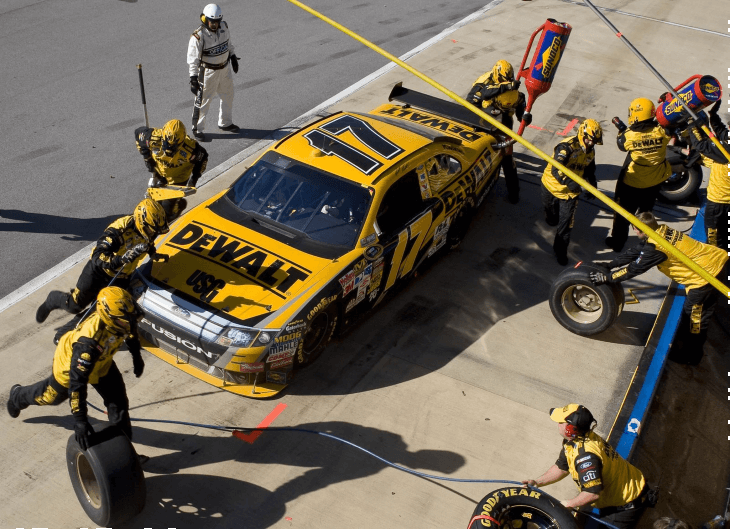

The world of NASCAR offers an excellent example of the power of an efficient changeover process.

For average people, changing a tire can take up to 15 minutes. A NASCAR pit crew can change a tire within 15 seconds. It goes without saying that in a race, every extra second off the track affects the outcome. But, it’s just as important to ensure the job is done correctly to avoid any tragic accidents. As a result, pit crews have perfected and optimized their movements to get cars in and out in as little time as possible while ensuring optimal outcomes.

Managers of warehouses, manufacturing plants, and distribution facilities can take inspiration from NASCAR pit crews. Their success relies on executing a number of steps before the actual process begins, performing several tasks in parallel, and standardizing as much of the process as possible.

SMED, short for single-minute exchange of die, is a process that allows warehouses, manufacturing plants, and distribution facilities to bring this efficiency to their operations through the following steps:

- Break up the changeover process into a series of steps, which SMED refers to as “elements”

- Convert as many of these steps or elements into tasks that can be performed while the necessary equipment is still in operation (i.e., elements that can become “external”)

- Remove or streamline (create SOPs for) elements that can’t be externalized

A Breakdown of the SMED Stages

Separate

At this stage, elements that can be performed before or after the changeover (i.e., performed while the equipment is still running) are identified. The separation process is the low-hanging fruit when it comes to demonstrating the ROI of your continuous improvement efforts.

Convert

At this stage, workers identify elements that can be converted and eventually externalized. Since executing on these changes can take some time, the list should be prioritized so the changes with the biggest impact can be adopted first.

Streamline

At this stage, processes that can’t be instantly or eventually externalized are re-evaluated. The point of this re-evaluation is to find ways to simplify these tasks so that they don’t burn as much time.

Short- and Long-Term Benefits of SMED Stages

In the short term, SMED processes make your warehouse more efficient.

In the long term, SMED processes allow you to be more responsive to customer needs and increase service levels in addition to reducing motion waste.

Eliminating Motion Waste Decreases Labor Costs While Increasing Productivity

Motion waste seems like an innocuous problem. What’s a few extra steps, right? But when you multiply those extra steps by dozens of workers, hundreds of shifts, and thousands of tasks, you’re looking at a huge sum of money you could have kept in your pocket. Identifying motion waste and taking strategic steps to eliminate them is an effective way to cut down on operational costs while amping up your service levels and productivity.

Want to use a WMS that can help your employees optimize their picking and putaway processes? Schedule your WMS demo today.

FAQs: Motion Waste

Q: What exactly is motion waste?

A: Motion waste, particularly in the context of warehousing, refers to any extraneous movement performed by workers that does not add value to the overall process. This could include extensive walking, reaching for items, bending, and so on.

Q: How does motion waste negatively impact warehouse operations?

A: Motion waste contributes to inefficiencies within warehouse operations. It can result in longer completion times, decreased productivity, and increased physical strain on workers. Over time, these inefficiencies can also lead to higher operational costs.

Q: What are some common examples of motion waste in warehouses?

A: Common examples of motion waste in warehouses can include walking long distances to pick items, bending or reaching for items unnecessarily, searching for tools or equipment, and sorting through disorganized inventories.

Q: How can we effectively minimize motion waste in warehouse operations?

A: Minimizing motion waste requires strategic planning and process optimization. Key approaches may include streamlining warehouse layouts, implementing efficient picking methods, adopting advanced warehouse management systems (WMS), and training staff on best practices.

Q: What are the benefits of reducing motion waste in the warehouse?

A: Reducing motion waste leads to numerous benefits such as improved efficiency, lower operational costs, enhanced worker satisfaction due to less physical strain, and a potential increase in overall output. Furthermore, it contributes to a smoother, more streamlined operation that can handle greater demands and complexities.

Run a digital fulfillment network and grow your DTC business–without additional headcount

Inventory Management

Improve your inventory across your supply chain.