WMS logistics software is more important than ever for modern supply chain management and direct-to-consumer (DTC) fulfillment. In the face of rising ecommerce orders and competitive delivery standards, logistics solutions provide visibility and control over one’s entire operation: from receiving inventory through order fulfillment and last-mile delivery.

If you’re a brand, online seller, or third-party logistics (3PL) provider, you know the ability to track warehouse inventory, incoming orders, fulfillment status, and carrier distribution is critical for maintaining a healthy supply chain and growing your fulfillment network. Let’s talk about the primary functions of logistics WMS software, how it helps improve efficiency across fulfillment operations, and strategies to ensure success during implementation.

In this guide, we’ll explore:

Understanding the Role of a WMS in Logistics

Key Functions of WMS in Logistics Operations

Logistics WMS software tracks all of the data moving throughout your operations, and utilizes built-in supply chain management tools to aid the ease and efficiency of fulfillment execution.

It’s more than just having insight into incoming online orders or the status of outbound shipments: WMS tools can help assess the health of warehouse operations and ensure all relevant processes are connected by one intuitive interface. The three most crucial include:

-

- Inventory Management

- Order Fulfillment

- Shipment Tracking

These are three of the most challenging areas of logistics operation track accurately. Luckily, a sound logistics WMS software can account for them.

Inventory Management

Managing inventory, especially for multiple warehouses, is a challenge for any company- regardless of whether you oversee B2B, DTC, or hybrid ecommerce fulfillment. WMS logistics software ensures that all the products entering and leaving your warehouses are accounted for and visible across your entire network.

To be clear, that includes damaged materials, returns, and items that need to be relocated elsewhere within your facility. With a logistics WMS software in place, you reduce the chance of inventory discrepancies, overselling items, overstock (not having enough warehouse space), and mismanaging your facility by reconciling inventory with sales orders and knowing the state of your products.

Order Fulfillment

When it comes to order fulfillment, keeping track of inventory isn’t enough. All of your inventory has multiple areas (sometimes with multiple processes) to go through before being shipped out for distribution and last-mile delivery. As a fulfillment provider, it is up to you to be able to know the status orders and the efficiency of these logistics processes.

In addition, WMS systems ensure the reconciliation between a shipment and its corresponding purchase order. With all available inventory and order data available in real-time across your departments, ensuring accurate order fulfillment becomes much easier. You no longer have to worry about having enough product to fill orders, determining whether or not the right product is going out for the right orders, etc. Everything can be tracked and managed within the logistics WMS software.

Shipment Tracking

While every company has steps in place to ensure that each order goes to the appropriate destination, a logistics WMS software can take it one step further by integrating with a shipping carrier to ensure packages that are out for delivery can be tracked and identified along the way.

This means that, even in a worst case scenario, if the wrong order ends up going to the wrong destination, then the mistake can be identified and remedied and adjustments can be made as needed.

Without a WMS to monitor live logistics operations, fulfillment operations have to wait for returns to arrive before confirming and adjusting order re-shipments. But with real-time data WMS logistics software, these mistakes can be caught sooner, so informed, cost-saving decisions can be made sooner.

Benefits of Using WMS in Logistics

With these three complex areas of the supply chain and logistics being simplified, it is clear that these key functions of a logistics WMS software tool benefit you, as well as your clients and customers. From complex inventory management to order processing and shipment tracking, cloud WMS software ensures smooth operation throughout your logistics chain.

Loss prevention gets easier, along with catching order discrepancies before they cause problems further down in your supply chain. Simply put, with logistics software supporting your operations, scaling order fulfillment is safer and easier as you grow.

Improving Warehouse Efficiency with WMS Software

While adjusting to a logistics WMS software might seem intimidating, the benefits clearly outweigh the costs. Here are some additional ways a WMS logistics software can improve efficiency for your logistics and supply chain operations.

Reducing Labor Costs

When you think about the processes of inventory management and shipment tracking, consider how much time is spent manually correcting mistakes, verifying orders and products, double checking inventory, tracking down lost or misplaced inventory, etc. How much labor is needed for these processes? How many employees do you have just accounting for data that could have been tracked across departments and automated for all departments?

Top-tier logistics WMS software leads to labor costs while boosting productivity.

Improving Accuracy

There will always be unavoidable instances of human error with any software, tool, or process. However, when data can be tracked in real-time and across multiple teams and departments, then it becomes much easier to catch the human error before they snowball into bigger data problems.

By improving the efficiency of pick-and-pack processes, decreasing time spent searching for inventory or replacing lost or misplaced items, and increasing the amount of orders fulfilled in a given time frame – a logistics WMS software becomes vital for logistics operations to thrive.

Increasing Productivity

In addition to reducing labor costs and improving accuracy, WMS software helps to automate operations using smart, customizable algorithms. Leave the days of hunting down materials behind and walking miles up and down crowded warehouse isles, and empower your operations to fulfill orders quickly and productively.

Even with a learning curve of adjusting to a new way of managing logistics operations data, there is still a significant spike in productivity for fulfillment operations that adopt WMS automation technology.

The Impact of WMS on Overall Supply Chain Performance

Overall, a high-quality, well-reviewed logistics WMS software tool can be a source of positive impact for high-volume fulfillment results. For ecommerce fulfillment operations, there is a massive advantage to leveraging WMS logistics software.

The right WMS logistics software in your company’s hands can feel tailor-made and streamline many processes and operations across your entire supply chain. It is a worthwhile investment, as long as you choose the best logistics WMS software that fits your needs and purposes.

The Logiwa WMS Approach to WMS Logistics

Key Features of Logiwa’s WMS Software

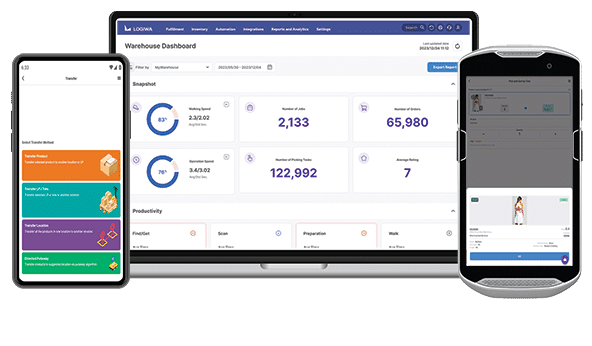

Logiwa WMS logistics software sets itself apart as a premiere cloud fulfillment solution for logistics and supply chain operations that are looking for the ability to scale, update data in real-time, and manage the entire logistics operation: from inventory management to door steps and store shelves.

Some of our key features for logistics WMS software solutions include:

- Cloud-based software for seamless data integration across departments

- 200+ software integrations including to ecommerce platforms, shipping, accounting, ERP, robotics, and more

- The ability to automate multiple operations from smart job batching to generating online reports

- Pre-integrated ecommerce connections so orders can be optimally routed based on product availability, shipping costs, and delivery times

- Automated shipping label creation, as well as the ability to quickly connect and automate orders with the best carriers for the order, and so much more

- Scalability, so your software can always keep pace with your growing company

- Legendary customer service (you can expect response times of as little as 7 minutes)

How Logiwa WMS Software Supports WMS Logistics

As a logistics WMS software, Logiwa WMS is specifically curated and geared towards maximizing benefits for ecommerce fulfillment operations. From our key features to our ability to implement WMS logistics fast, Logiwa WMS supports logistics and supply chain operations with every tool in our platform.

There are countless ways to streamline and optimize fulfillment processes for your logistics operation when you turn to a WMS. Yet Logiwa WMS was created to go above and beyond being an efficient inventory management or order fulfillment system. It stands as an all-encompassing logistics WMS software platform for any and every stage of the logistics and supply chain industry.

Implementing WMS in Logistics

Steps Involved in Implementing Logiwa WMS Software

Implementing logistics WMS software can be tricky. However, Logiwa WMS has done everything possible to make the implementation process smooth and seamless for our clients and their customers.

We take a four-step approach to efficiently implement our logistics WMS software, including: business process and change analysis, configurations testing, training and practices, a series of dry runs, assisted go-live care, and follow-up support for a positive post-implementation experience. When possible, we even complete your first order with you.

Your WMS will likely be constantly evolving and changing as your business grows and develops, but here’s what to expect with a standard WMS implementation:

Assessment

As you begin to select a logistics WMS software solution, like Logiwa WMS, carefully assess what your business needs are and how they align with the features and tools within the WMS software.

Furthermore, you need to be able to constantly assess how implementation is going up to this point, see where you can improve, and assess once changes have been implemented. Make a granular list of every functional need your operations will require to be successful.

Selection

It goes without saying, but selecting the right logistics WMS software is a critical phase before the implementation process. Selecting the tools and features you will need most, and confirming with your provider that each and every functionality will be met, should happen before signing on to begin implementation.

Don’t feel like you can’t pivot to a different method of using a tool or feature if it seems to make more sense down the line.

The Importance of Proper Planning and Preparation

Now, before you can truly start implementation, you have to give careful consideration to planning and preparation. Largely, this means getting your data organized. This is the most cumbersome task because you want to make sure you are implementing clean and accurate data within your WMS – so make sure your timeline is realistic.

Customization

Every logistics WMS software should allow for some level of customization to better adjust to your specific company’s unique needs. This is something Logiwa WMS exceeds at, especially during the implementation process. You need to make sure your WMS logistics software suits your needs, not the generic needs of every logistics operation everywhere. After all, software is not one size fits all.

Testing

As you learn and become more comfortable with the onboarding process of your logistics WMS software, you will need to repeatedly test out core features and tools before going live with the solution. Keep careful track of what settings, tools, and features you are using and how. Make sure to keep the best ones and address any problems you may come across.

Deployment

Finally, careful consideration should be given to the final rollout and deployment of your logistics WMS software. Ideally, you will do this alongside your provider. With Logiwa’s customer service team at your side, our industry-leading Logiwa WMS can be implemented in as little as 4-6 weeks!

Ready To Optimize your WMS Logistics Operation?

Choosing the right WMS logistics software is a difficult and lengthy process. A great WMS software solution can increase efficiency of your logistics operation, but the wrong choice can be detrimental to the success of your business.

Logiwa WMS was created for all phases of the logistics and supply chain operation, and our team is there to help guide you along the way. Set up a time to talk with one of our warehouse management experts and book a non-commitment demo to see how Logiwa WMS can transform your brand and fulfillment operations today.

Run a digital fulfillment experience with a fully integrated Cloud Logistics WMS Software

Warehouse Management

Modern digital WMS powers a modern fulfillment experience