Fulfillment Solutions with Erhan Musaoglu

We sat down with Logiwa Founder & CEO, Erhan Musaoglu, to discuss the importance of warehouse automation for optimizing inbound and outbound fulfillment logistics.

How much of the inventory management and order fulfillment process can be automated? Where are the limitations?

Musaoglu: The simple answer is that most warehouse processes can be automated, at least to some degree. The important thing to realize is that there are two types of automation: physical and facilitatory within a fulfillment center. The first type, physical automation, includes hardware, material handling equipment, and robotics – anything that takes over physical jobs for you and your team. If it replaces manual labor and carries out tasks like putting products away or picking items for order processing, it is considered physical automation technology. Within this category, there are also packing machines that can create the packaging for products and “sorters” which can sort thousands of items into smaller orders.

The second type of automation – which can be collectively referred to as “facilitators” – are automated flows such as automation rules, automated workflows and algorithms. This type of automation is aimed at process improvement. Without automation rules, warehouse employees are required to make a lot of time-consuming, manual decisions. Directed putaway is a great example of a facilitator because it programmatically suggests the best location for items. Without it, an employee has to search to determine the best location on their own. And chances are, they will find the first available location, not necessarily the best location.

Job creation and picking algorithms are other ideal examples of facilitators. Using this type of automation technology, items can be grouped in a way that limits the walking distance and number of visits a picker has to make to a single location. Picking algorithms determine the right products to allocate to orders, using logic such as First Expire First Out (FEFO) or First In First Out (FIFO) approaches, to route the pickers to the right location for the product that needs to get out the door first.

Inbound operations set the stage for the entire fulfillment process, but is one process more important to optimize than another? Receiving? Putaway?

Musaoglu: In my opinion, putaway is the most important to optimize. If you talk with other supply chain experts, they will likely say that optimizing the picking process is more crucial. However, if you don’t put products in the optimal place first, you cannot begin to improve your picking operations or increase the output of your fulfillment center. The most important process is the one that affects all others. Putting your products in the right place optimizes your warehouse and every other process that occurs downstream in your fulfillment operations.

What are some examples of the gains/impacts that can be achieved by optimizing each?

Musaoglu: When it comes to optimizing warehouse and fulfillment processes, Logiwa weighs impact from three primary measurements. The first is number of orders. Once a process is automated, how much does output increase? How many orders are being shipped in comparison to before the automation was in place? The second measurement is time. How much time are customers saving each day? The third, of course, is cost. What is the financial impact based on the time saved for our customers? Of these three, the number of orders shipped is the most important.

Let’s talk through a tangible example. Today, for instance, I learned that we improved one of our customer’s label printing processes from six seconds to two seconds. Four seconds of improvement might not seem like a lot, but this customer was shipping 5,000 orders a day, which means 20,000 seconds – or more than 5 ½ hours – improved daily. When you do the time conversion, it’s easy to see how many more orders they can ship with the same number of employees.

When it comes to automation, shipping volume is increased, time is gained, and money is saved across the board.

How do warehouses choose the best putaway method for their operations as they continue to evolve?

Musaoglu: There is no one size fits all, in terms of choosing a “best” putaway method. It depends on your product and your warehouse. From your layout, types of products and numbers of items you’re storing to your operational business model – whether you’re direct-to-consumer (DTC) or B2B – all are critical factors when formulating your putaway strategy, especially as you change.

For example, if you have 100,000 different products in your warehouse at a given time, and your warehouse is just 10,000 locations, then you have to put multiple products in the same location. In this case, the best approach would be using a chaotic putaway algorithm, which has employees put items in the best place that they think will fit their day-to-day picking operations. But of course, there are restrictions or constraints that need to be applied to this method, such as keeping chemical products far away from food items and ensuring that similar items are not stored next to each other. Without constraints in place, employees can make costly mistakes. They are forced to slow down and check item codes every single time they go to an area.

A WMS can help with clarifying constraints, so employees don’t put the wrong items next to each other. That said, there is no automation or good software to execute chaotic putaway because employees are the deciding factor. Of course, this is only one method. Putaway based on picking optimization is often a much better choice. When you put away items in a way that allows you to pick them faster, the results are better long-term.

Because, with fulfillment centers, the main idea is to ship products faster, a.k.a. getting them in and out of your facility as quickly and efficiently as possible. Directed putaway algorithms increase picking efficiency and use rules that suit the individual characteristics of your products and facility, which can evolve as your operation does. For example, placing fast moving items closer to shipping areas or packing areas, or creating a zone specifically for oversized items. Putaway can remain flexible and involve more than one approach with the help of the right WMS fulfillment solution.

Is it wise to pick one picking method and stick with it? What about using multiple picking styles within one operation?

Musaoglu: Without automation, such as if you are using an excel sheet or spreadsheet, executing multiple picking methods is extremely limited. Your job types, picking options, and overall fulfillment strategy must remain simple enough for the human brain to understand. For strictly manual operations, you may have one or two picking methods at most, and both will be strictly order based.

But with the assistance of modern fulfillment technology – which incorporates machine learning, data analytics, and artificial intelligence (AI) – using multiple picking styles becomes possible. No matter how many different flows you have going on, you can implement different picking methods to support each. As a basic example, you can batch all your single items into one pick job. Then, at a smart packing station, you can simply print labels and pack up each order. The same goes for identical items. If you have 200 individual orders of one item, you can pick them and process them in one all-encompassing trip.

Cluster picking is another option, which would mean picking anywhere between 8 to 12 orders that are close to each other and have similar items. This method reduces pickers’ walking distance as well. It is different from putaway in that you want to pick similar orders together. And for oversized items, you would need to take an order-based picking method. The point is, multiple picking methods are possible and can greatly increase the efficiency of fulfillment operations. But you need a putaway approach and the help of a smart WMS to accomplish it.

How does scanning technology help with the accuracy and speed of inbound/outbound operations?

Musaoglu: Automated warehouses should use some form of scanning technology or wireless technology like RFID. Visual scanning also works, which is when a camera identifies a product based on image comparison. Otherwise, you are leaving your accuracy entirely up to a human. And humans are prone to mistakes. They are heavily influenced by factors like exhaustion, environmental factors, their state of mind, and so on.

Without scanning technology, employees are forced to read item barcodes in order to confirm they’ve picked the right item. That is a fully manual process, and it means there’s no truly dependable verification going on. Accuracy is guaranteed to go down and lead to a number of problems, such as customers receiving incorrect products and inventory discrepancies within the fulfillment center. With scanning technology , RFID, or visual scanning in place, you eliminate the possibility of those mistakes. Even if a worker picks the wrong item, the system can alert the employee that it is the wrong product.

Even though using hand-held scanning technology adds to picking time, because one hand is available for picking instead of two, the time saved by avoiding inventory mistakes and misshipments is tenfold. Just consider the added time it takes to fill an order in a location where an item was supposed to be but isn’t actually available. Or the time and resources that it takes to process a return and re-do an order because the right item did not get shipped the first time. This can add a week or more to a single order. So even though scanning technology technically slows operations at the beginning of the process, the time it saves overall is far more significant because it eliminates mistakes.

Optimizing every stage of fulfillment is important, but which warehouse process do you feel is neglected the most?

Musaoglu: Putaway is the most neglected warehousing process. Everyone understands the importance of high-efficiency picking, yet putaway is easily ignored in comparison. The reason for this is because it is not easy to see the cost of poor putaway strategies directly – there’s nothing to measure outright. But when you see the effects an optimized putaway process has on operations – results like faster picking – it’s clear what a difference it makes overall.

That said, order grouping or order batching are also critically important. Because warehouses are live environments. Let’s say there are 10,000 different bins or locations, and there are 100,00 different products… and you’re picking 10,000 orders every day. The combinations are unlimited. A modern WMS with machine learning and other technology. can put similar orders together, which means a picker walks less. And if they are picking a lot of similar orders, they can do batch work. This is key to automation and warehouse efficiency.

How does automation enhance the performance of operations? Where do automated workflows within the WMS come in?

Musaoglu: Nearly every part of fulfillment logistics can be automated. From receiving and putaway, picking and packing, and shipping… to the granular processes of shipping box suggestions, label printing, and carrier suggestions based on rate shopping. Each one of these order processing and fulfillment functions is accounted for within the WMS system.

Here’s another example. During a site visit to one of our clients, the Logiwa team noticed that the same package type was always being used. It was taking 5 seconds every time the packer clicked the dropdown list, scrolled through the options, and selected the exact same pack type for every order. By helping them set up a new automation rule, we helped them assign the package type for that specific client and eliminated the step entirely.

Since that client ships approximately 3,000 orders per day, saving them 5 seconds per order amounted to 15,000 seconds – nearly four and a half hours – saved each day. With ten staff working 8-hour shifts, this particular warehouse team was using 80 hours to pick 3,000 orders, or a little less than 40 orders per hour. With the hours saved through automation, they were able to start picking an additional 156 orders per day, so more than 3,000 more each month.

Some additional examples of how automation enhances operations include rules that create picking jobs that group orders based on specific priorities, like items being in the same Zone, or encompass approaches like ‘pick and pass’ strategies for orders that need items for more than one zone. It leverages carrier rate shopping to execute the best shipment method and price for each order – saving you money. It uses integrations with ecommerce platforms and marketplaces to ingest and route orders for streamlined workflows. The list goes on. Ultimately, automation rules minimize decision-making for expedited operations.

What does end-to-end fulfillment mean?Are processes like replenishment, quality control checks, and inventory transfers included in end-to-end fulfillment? How does automation enhance these?

Musaoglu: End-to-end fulfillment, in its truest sense, encompasses each stage of fulfillment and its overarching supply chain logistics. From the procurement of items from vendors and manufacturers through last-mile delivery to consumers. It can include freight management and ocean transportation, as well as processes like inventory transfers and quality control.

Logiwa’s automation technology helps address the processes within fulfillment centers, which are a core segment of this overarching supply chain process. Our automation optimizes the speed, accuracy, and cost-efficiency of end-to-end fulfillment center operations. By automating order management, inventory processes like putaway, picking and replenishment, and shipping logistics operations achieve greater throughput and fulfillment results.

How do modern warehouse management systems (WMS) like Logiwa streamline warehouse operations and online order management?

Musagolu: Logiwa’s WMS fulfillment solution downloads orders, finds the best fulfillment centers to fulfill those orders, and directs inventory and order management processes to expedite shipping and ensure fulfillment accuracy. For operations needing to achieve two-day fulfillment and other complex DTC fulfillment requirements – a traditional WMS is not enough. These sorts of competitive standards are beyond a normal WMS’s functionality.

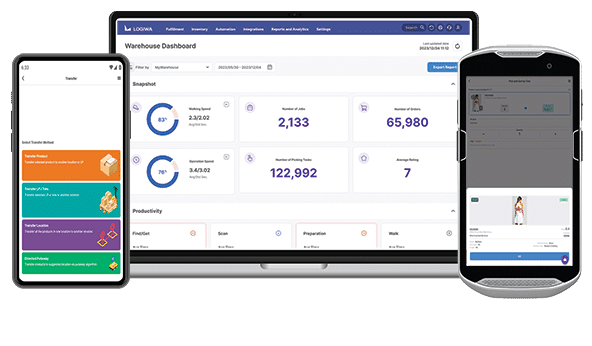

Logiwa is more than a WMS. It’s a true fulfillment solution, including multi-channel ecommerce order management and the capabilities of leading shipping platforms. Our integrations and streamlined approach to order fulfillment use AI and machine learning to optimize these processes. For businesses to get ahead, they need the scalability, flexibility, and multi-functionality achieved that’s possible. That is what Logiwa was built for.

Scale up B2C fulfillment operations with an integrated digital warehouse and fulfillment system

Warehouse Management

Modern digital WMS powers a modern fulfillment experience