Warehouse automation has become the key to making operations more efficient, accurate, and cost-effective. By using automation, warehouses can reduce labor costs and improve inventory accuracy. However, to enjoy these benefits, choosing the right warehouse automation system is essential.

Warehouse automation systems can be hardware or software. Hardware includes tools like conveyors, robots, and transportation systems that handle storing, sorting, picking, and moving inventory. Software includes warehouse and inventory management systems that control these automated processes.

Here we’ve highlighted eight of the best systems available today. While compiling the list, we kept the following in mind:

- Warehouse automation should streamline inventory management from receiving to shipping.

- Improvement should be seen in safety, productivity, cost savings, and space usage.

- Automated systems should provide actionable data to improve warehouse operations.

- Consider pricing, features, scalability, and ease of use.

Contents

The benefits of warehouse automation systems

Some of the key advantages you can expect when using warehouse automation systems:

- Increased efficiency: Automation speeds up tasks like picking, packing, and shipping, making operations faster and more accurate. This leads to better order fulfillment and higher customer satisfaction.

- Lower labor costs: Automation reduces the need for manual labor in repetitive, physically demanding jobs. By cutting labor expenses, your warehouse can become more profitable.

- Better use of space: Automated systems help organize inventory more efficiently, ensuring no space is wasted and items are easy to locate.

- Real-time inventory tracking: Automation provides instant visibility into stock levels, helping you avoid overstocking or running out of items.

- Improved safety: Robotic systems take over dangerous tasks like moving heavy items, reducing the risk of injury and keeping workers safe.

- Data-driven insights: Automated systems generate data that can help you spot problem areas and improve warehouse performance.

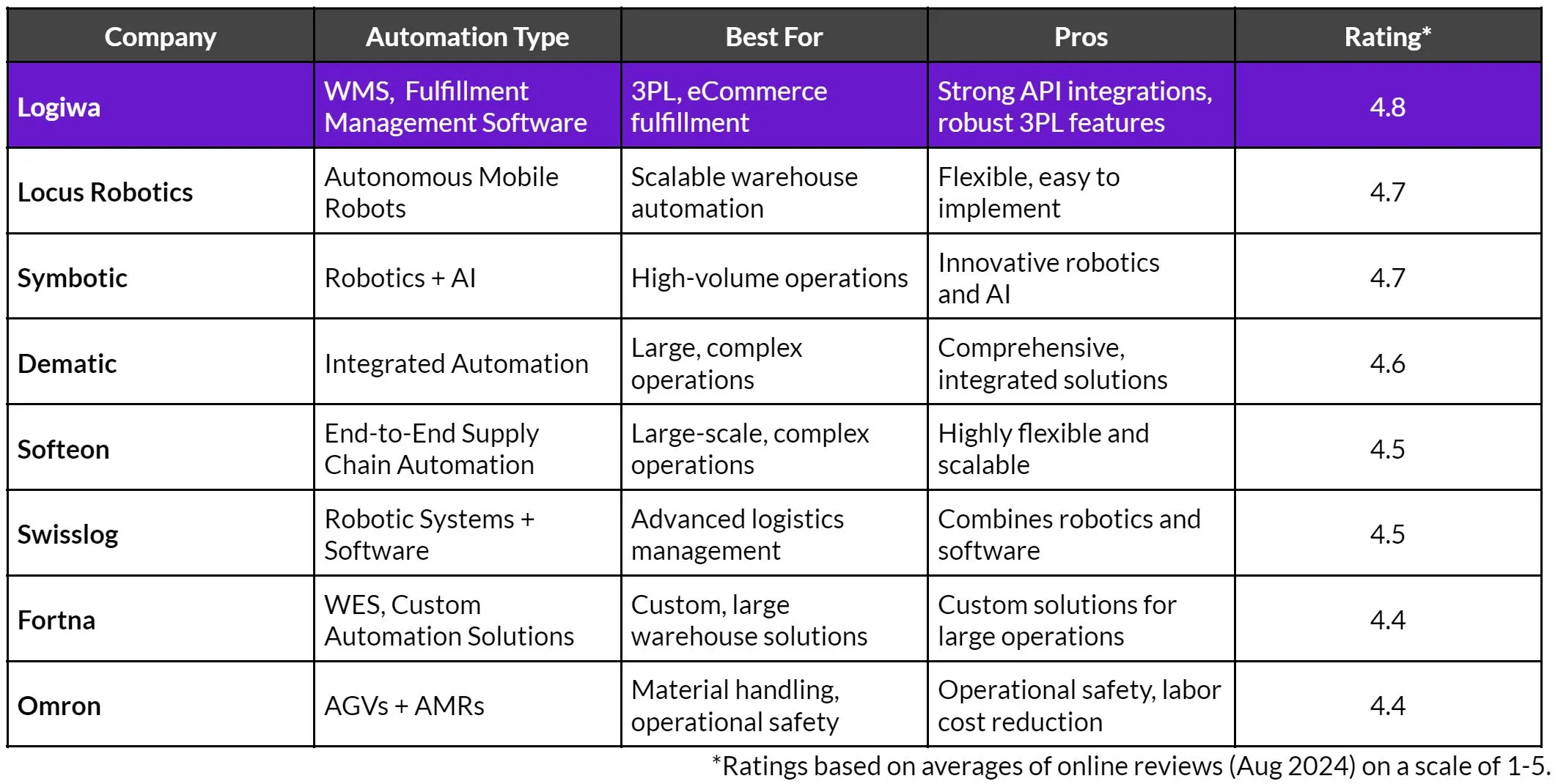

Best warehouse automation systems comparison table

1. Logiwa

4.8/5

2. Locus Robotics

4.7/5

3. Symbiotic

4.7/5

4. Dematic

4.6/5

5. Softeon

4.5/5

6. Swisslog

4.5/5

7. Fortna

4.4/5

8. Omron

4.4/5

Unlock a personalized tour of Logiwa IO

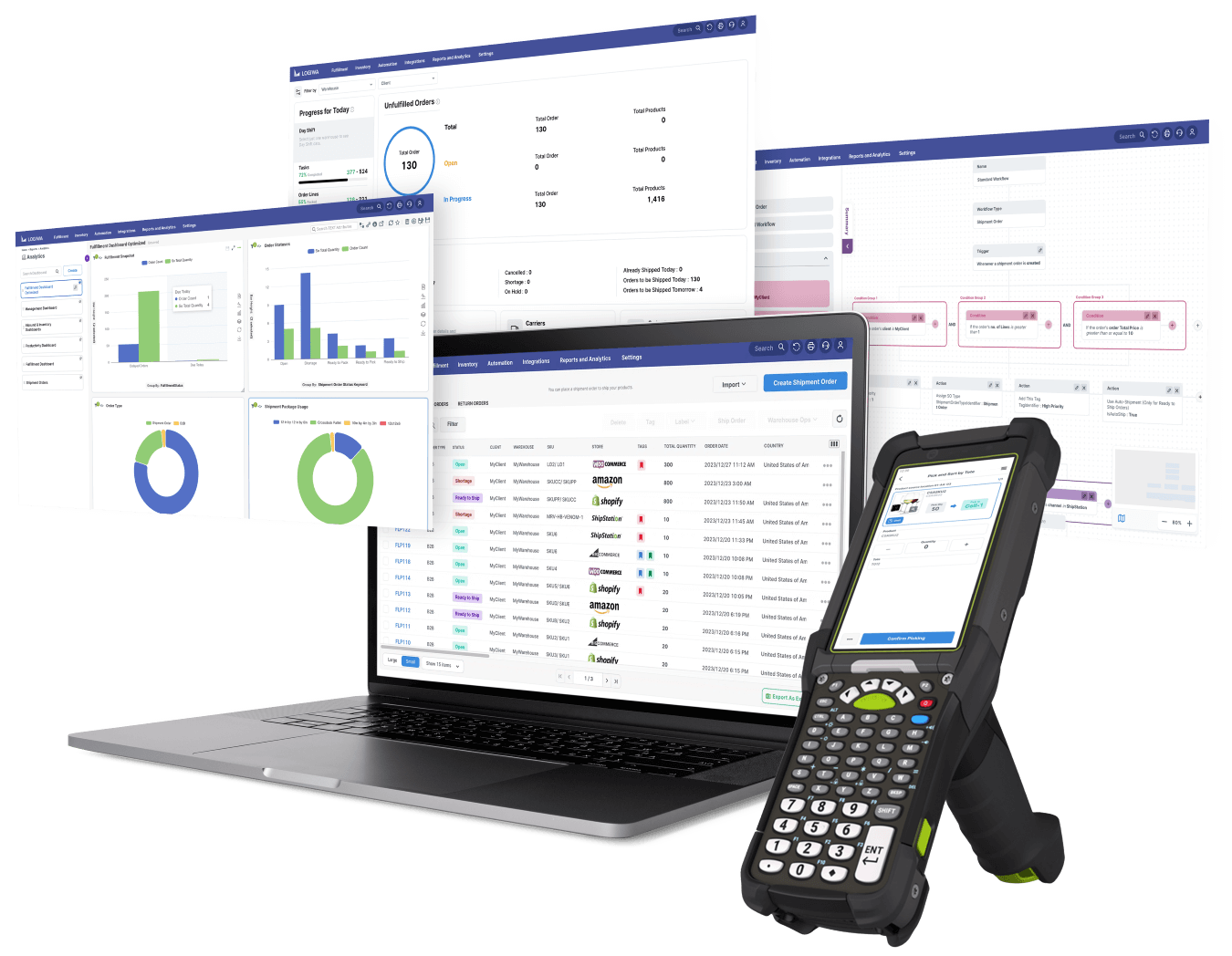

How Logiwa aids warehouse automation

Logiwa IO goes beyond legacy WMS offering a fulfillment management system (FMS) that helps manage and automate all your warehouse equipment and processes. It easily connects to automated systems, giving you real-time insights.

Logiwa IO also automates tasks like billing, assigning work, rate shopping, and label printing. Logiwa is affordable, scalable, and flexible, making it a great fit for any warehouse.

Schedule a call with one of our fulfillment specialists to discover the many benefits of Logiwa IO for your operations.