Key Takeaways:

- Inbound logistics focuses on the transportation and storage of goods coming into the warehouse, while outbound logistics deals with transporting goods to customers.

- Streamlining both inbound and outbound logistics processes can significantly enhance supply chain efficiency and customer satisfaction.

- An integrated supply chain management strategy centralizes operations, fostering efficiency and cost reduction.

- Technology, such as Logiwa’s solutions, can provide visibility and optimization across the entire supply chain.

- Effective supply chain management, encompassing both inbound and outbound logistics, is crucial for business growth and customer retention.

“If managing the supply chain is like fetching a hungry baby a bottle, then logistics is the thankless trek up and down the stairs in the middle of the night.” ~ Benn Bekic, CSO, WiseTech Global

According to Deloitte, 79% of companies with high-performing supply chains surpassed industry competitors in terms of revenue growth. Comparatively, only 8% of companies with average supply chains realized above average growth. How do your inbound logistics and outbound logistics compare?

In this guide, we’ll help you understand:

- Comparing Supply Chain Management and Logistics

- Why Is Supply Chain Management So Critical?

- What Is the Difference Between Inbound Logistics and Outbound Logistics?

- How to Optimize the Inbound Logistics Process

- How to Optimize the Outbound Logistics Process

- The Advantages of an Integrated Supply Chain Management Strategy

- Improving Inbound and Outbound Logistics Is an Important Part of Effective Supply Chain Management

BONUS: Before you read further, download our Warehouse Management Software Whitepaper to see how Logiwa uses real-time data to help you get up to 100% inventory accuracy and execute advanced fulfillment strategies like wave planning.

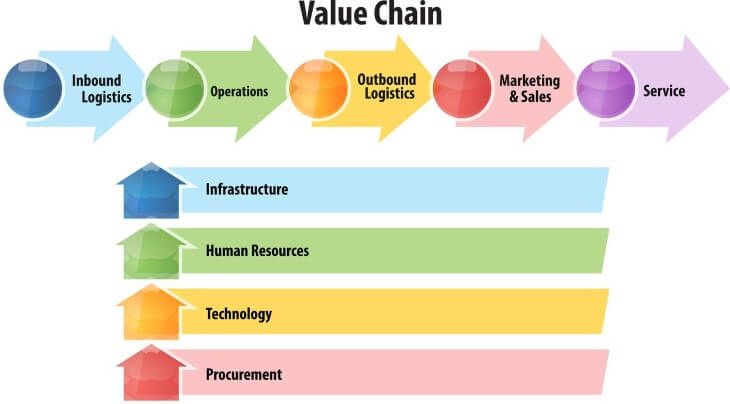

Comparing Supply Chain Management and Logistics

Supply chain management is one of the most poorly understood elements of a business. That’s despite the fact that it accounts for the lion’s share of a company’s costs. Oftentimes, the supply chain and logistics processes within businesses aren’t strategically designed. Instead, they develop over time and are rarely scrutinized.

According to Benn Bekic, Chief Strategy Officer of WiseTech Global, this is the difference between logistics and supply chain management. Observers often use the terms interchangeably, but they certainly aren’t synonymous.

Your inbound logistics and outbound logistics include everything required to get a product from one point to another.

On the other hand, supply chain management covers every movement involved to get a product to the customer.

Still sound like they’re the same thing? Hardly. Logistics covers the nitty-gritty, as Bekic’s quote demonstrates, while supply chain management looks at the big picture. Supply chain management is a strategic activity, while logistics is the implementation of that strategy – and the occasional deviation from it.

Another way to differentiate logistics is by considering the role of different businesses. Logistics concerns the movement of goods within one company, whereas supply chain management covers the movement of goods through different businesses in the supply chain. For instance, the supply chain for baked goods would include the farmer, the warehouse operator, and the baker.

| Logistics | Supply Chain Management |

|

|

Why Is Supply Chain Management So Critical?

Supply chain management and logistics are vital to running a successful business. In the past, supply chain management and logistics didn’t earn as much attention as business activities like research and development, product marketing, and sales.

Recently, however, it’s attracted the attention it deserves, and rightly so. Supply chain management, and its component function logistics, are important for the following reasons:

- A beautifully designed and packaged product isn’t worth anything if your customer never receives it

- A company that can efficiently process, store, and transport raw materials, semi-finished goods, and finished goods will increase profits by streamlining operations

- A brand that manages to deliver goods accurately and on schedule increases customer satisfaction and loyalty and increases the likelihood of repeat customers

- A business that understands all facets of its supply chain avoids working with unethical supply chain partners, protecting its reputation and from legal damage

You should note that supply chain management and logistics management aren’t just for large companies. By understanding the essentials of these disciplines, small to medium sized businesses can also improve customer satisfaction and reduce operating costs.

In this guide, we will focus on the inbound logistics and outbound logistics function of supply chain management.

What Is the Difference Between Inbound Logistics and Outbound Logistics?

Many business functions fall into the category of logistics. These include functions such as fleet management, warehousing, and materials management. However, the concept of logistics can generally be divided into inbound logistics and outbound logistics.

Inbound logistics covers the transportation and storage of goods coming into the warehouse. Typically, this includes the relationship between a warehouse and its suppliers of raw or semi-finished goods.

Alternatively, the outbound side refers to the transport of goods leaving the warehouse. Generally, this covers the relationship between a warehouse and its customers.

Both inbound and outbound logistics processes are important for overall supply chain management strategy. While the inbound logistics process might include everything from raw materials to tools, outbound logistics is primarily concerned with end products ready for use by customers.

How to Optimize the Inbound Logistics Process

Experts consider the inbound logistics process “the final frontier” for companies who wish to reduce transportation costs. Streamlining this process is difficult and requires considerable effort from supply chain managers and warehouse operators. At a high level, improving inbound logistics includes the following activities.

Building Strategic Relationships with Your Supplier Partners

Determine your most optimal route and work with suppliers to implement it in a way that’s beneficial for both parties. Create a routing guide as part of this process to clearly define operating procedures and rules of engagement. Your routing guide will include:

- Modes and carriers to use in certain lanes

- Rate requirements

- Service requirements

While routing guides can be physical or digital, experts recommend online routing guides. They can adapt to changes in the shipping landscape such as fluctuating rates.

By implementing a routing guide, you can limit rogue expenses by suppliers. For instance, it introduces rate benchmarks and eliminates the use of non-authorized carriers. Naturally, though, a routing guide is most effective when a particular individual or business unit is in charge of overseeing and updating it.

Developing and Implementing Vendor Inbound Compliance Standards (VICS)

Specific supplier behavior hinders a company’s ability to manage a streamlined, efficient supply chain. So you’ll want to develop Vendor Inbound Compliance Standards (VICS) that all suppliers must agree to in order to work with your company. By reinforcing positive behavior and establishing penalties for negative ones, you can optimize your inbound logistics process.

Keep in mind, though, that it’s not enough to just develop VICS. You must include penalties for non-compliance in the VICS and apply these penalties consistently. For one, this ensures suppliers take your compliance requirements seriously. For another, financial penalties offset the cost of inefficient practices.

Using a Transportation Management System (TMS) for Dynamic Rates for Freight Costs

Businesses often accept the freight costs their vendors quote due to lack of visibility over market rates. But, with a transportation management system (TMS), your company has access to changing rates based on market conditions. You can use this information about carriers and routes to set real-time vendor allowances. This ensures that you get the best rate possible and keep costs low.

Better Warehouse Performance = Higher Profit Margins: Logiwa syncs accurate data across your entire interface so the inventory numbers you see on your dashboard are what your employees see on their devices. Learn how Logiwa uses real-time data to help you get up to 100% inventory accuracy and 2.5x shipments.

Consolidating Your Inbound Freight Deliveries

Less-than-truckload (LTL) shipments are inefficient and lead to unnecessary costs both in terms of shipping and unloading. Indeed, when a company unloads 10 to 14 different LTL shipments, it spends 5 times more than it would unloading just one truckload.

So, by consolidating LTL shipments into full truckloads, your company saves money. Of course, there are challenges associated with this strategy especially when working solo. To reap the benefits of full truckload transportation, you have to think about the following logistics considerations:

- Specific shipping and handling requirements

- Point of origin and final destination of the shipment

- Shipment weight

- Departure time and arrival time of shipments

- Availability of drivers

- Availability of trucks

- Current fuel costs

Sometimes, although they would benefit from implementing it, companies can’t pull off a full truckload transportation strategy on their own. In such cases, you can use the services of a third-party logistics company (3PL).

How to Optimize the Outbound Logistics Process

We’ve seen that the inbound logistics game is about checking whether your vendors and suppliers keep you happy. On the other hand, the outbound logistics process is about getting your products to customers. Essentially, you must ensure your customers remain happy with you.

On the face of it, this sounds simpler than inbound logistics. However, there are several variables involved in a successful outbound logistics operation. These include:

- Warehousing inventory

- Processing orders

- Order Picking

- Efficiently packaging finished goods

- Transporting finished goods to customers

- Scheduling drivers and warehouse staff

- Working with third-party transportation companies (if applicable)

When it comes to getting finished goods to consumers on time and to their requested specifications, there are steps warehouses can take to improve their outbound logistics processes.

Many of your warehouse operations can be streamlined with an order fulfillment system. Implementing a system would improve your outbound logistics operational performance.

Negotiate with Your Carriers for the Best Rates

Everything is negotiable. So, if you work with third-party carriers, don’t assume that the rate you’ve been given is the shipping rate you must accept. Build a relationship with your carrier account manager. At the same time, explore potential points of negotiation. There are several areas of your shipping agreement that you can negotiate. It would be better to use shipment rule automation algorithms to optimize the shipping rules.

To start, carefully review all aspects of your current shipping agreement, including next-day air rates and surcharges. Look through your shipping data to understand where you’re spending the most money.

Once you have an understanding of your shipping activity and business needs, negotiate volume discounts or initiate an RFP process to solicit the best offers from multiple carriers. Here you can check our page to learn best shipping strategies for new-age fulfillment businesses.

Reduce Your Inventory Costs

Managing inventory costs keeps warehouse costs low. Remember: the outbound side is about getting products to customers on time. One of the ways you can do this is by ordering more products than you need to ensure you can swiftly respond to demand fluctuations.

Watch out though — while inventory prevents stockouts, too much of it could increase your outbound logistics costs. You’ll need to pay for staff to inspect and count inventory, premiums to insure the goods, rent to store the products, and more. Some useful strategies for keeping inventory costs low are:

- Using safety stock formulas

- Applying lean management techniques

- Adopting a vendor managed inventory (VMI) strategy

- using an inventory management system

Using Cross-Docking for Your Warehouse Operations

Cross-docking limits the amount of time goods spend in your warehouse. Workers sort incoming goods before quickly transferring them to an outbound truck. While it isn’t suitable for every business, employing a cross-docking approach allows businesses to use less warehouse space and minimize material handling.

Cross-docking also increases product quality, reducing the number of ecommerce returns and increasing customer satisfaction. During the staging process, where products are temporarily kept on the dock before shipping, workers can quickly inspect products and remove damaged finished goods from the outbound shipment.

Wal-Mart is famous for its excellent supply chain management strategy and cross-docking plays a prominent role in both its inbound and outbound logistics processes. In fact, optimizing the supply chain was a primary focus for Wal-Mart from the company’s start and allowed the famous retailer to offer the low prices it’s known for today.

The Advantages of an Integrated Supply Chain Management Strategy

Your company’s supply chain extends beyond its four walls. It encompasses your entire network of factories, suppliers, warehouses, distribution centers, and retailers. Moving through this supply chain are raw materials that are processed, stored as finished goods, and shipped to consumers.

Traditionally, supply chains existed in silos and many still do today. In this unintegrated supply chain model, however, each logistics function operates with its own goals in mind.

This is large because there are often entirely different businesses involved. The functions will concern themselves with one, but not all, of the following supply chain management goals:

- Timing

- Cost

- Inventory accuracy

An integrated supply chain takes an “enterprise resource planning approach” to the supply chain. It doesn’t use a disjointed process with several businesses that work with separate objectives.

Instead, an integrated supply chain takes a centralized approach where managers build relationships with partners and all activities flow through one system. This way, an integrated supply chain makes businesses more efficient and reduces costs.

That said, you might face challenges building the necessary technology infrastructure and convincing supply chain partners.

In some cases, companies adopt a vertical integration approach to their supply chain. Rather than relying on other businesses, they start companies designed to fill specific functions in their supply chain. This reduces both dependences on suppliers and potential hold-ups.

Improving Inbound and Outbound Logistics Is an Important Part of Effective Supply Chain Management

Inbound and outbound logistics are pivotal elements of a company’s supply chain. A robust inbound logistics process ensures businesses collaborate with top-tier suppliers, while an optimized outbound process guarantees customer satisfaction, leading to repeat purchases. Harness the power of Logiwa’s smart shipping to streamline your workflows and establish efficient standard operating procedures. Embrace cutting-edge technology to gain unparalleled visibility across your entire supply chain. Prioritize supply chain management with Logiwa, and regardless of your company’s size, tailor the best strategies and techniques to elevate your business operations.

FAQs: Inbound and outbound logistics

Q: What are the primary differences between inbound and outbound logistics?

A: Inbound logistics focuses on the transportation and storage of goods coming into the warehouse, while outbound logistics deals with distributing products to customers.

Q: How can businesses optimize their inbound outbound logistics processes?

A: Businesses can streamline their inbound outbound logistics by developing standard operating procedures, using technology for visibility, and collaborating with reliable suppliers and efficient distribution channels.

Q: Why is it essential to have a strong inbound logistics process?

A: A robust inbound logistics process ensures that businesses work with the best suppliers, leading to quality products, timely deliveries, and cost efficiencies.

Q: How does outbound logistics impact customer satisfaction?

A: An effective outbound logistics process ensures timely and accurate deliveries, which enhances customer satisfaction and encourages repeat purchases.

Q: Can technology play a role in improving inbound outbound logistics?

A: Absolutely! Leveraging technology, like Logiwa’s solutions, can provide comprehensive visibility, optimization, and efficiency across both inbound and outbound logistics processes.

Related Terms

Put Walls

In this blog, we will define Put Walls, outline their benefits, and provide guidance on how to get started using them.

ABCs of Warehouse Management System

Warehouse management systems can be complex. Explore what is involved and how it can help your warehouse operations.

Warehouse Logistics Software

Which is the better warehouse logistics software? Compare warehouse management systems and warehouse execution systems.

inVia Robotics

inVia provides next-generation autonomous mobile robotics and warehouse automation solutions for ecommerce distribution centers and more.

6 River Systems

6 River Systems (6RS) offers autonomous robots, artificial intelligence & operational expertise for 3PL, ecommerce, retail and B2B.

Locus Robotics

Locus Robotics builds innovative, autonomous robots that collaborate with WMS to meet the challenges of today’s growing logistics industries.

Automated ecommerce shipping software pre-integrated with your carriers

Warehouse Management

Modern digital WMS powers a modern fulfillment experience