Inventory takes up storage space, can become obsolete, and can cost your business time and money. Yet, in a 2020 BCI survey, more than 12% of business leaders thought inventory management planning didn’t apply to their operations. In reality, there is actually nothing more important than inventory!

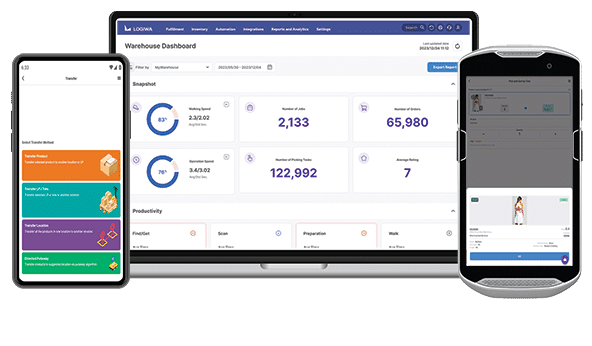

Getting inventory onto your shelves and back out the door quickly is essential for any warehouse or fulfillment operator. Logistics management technology and software can help improve your inventory processes, saving you time and money while increasing client and customer satisfaction.

Before we jump into logistics management software and technology, let’s get back to basics!

Contents

What is Inventory Logistics?

Inventory logistics, sometimes called third-party logistics (3PL for those keeping track), is the process of planning and controlling the receiving, storage and shipping of goods and materials. Inventory logistics or third-party logistics provide valuable information about the flow of these goods or materials through your warehouse. It includes product availability (we all know how COVID-19 affected global supply chains), storage, inventory replenishment, order fulfillment, and item returns. It also consists of the data you use to record your inventory, such as SKUs, lot and serial numbers, cost, other product descriptors, or expiration date.

Inventory logistics can be difficult to manage by hand. The intricacies of all of the moving parts leave a lot of areas that can go unnoticed, creating a problem down the road in the supply chain. Implementing logistics software can positively impact your warehouse operations, including improved inventory planning and ordering, improved warehouse organization, increased productivity, and increased customer satisfaction.

How Does Inventory Logistics Impact My Business?

According to Logistics Management, inventory costs can rival transportation costs as the highest cost for warehouse operators. Inventory costs often hold the most opportunity for significant improvement once an organization starts to pay attention to them. Ignoring inventory costs can lead to increases in space and labor costs and could even drive customers away, resulting in reduced profits.

Space-related costs

Inventory needs a place to live before getting shipped to customers. It needs space, whether on a shelf, on the floor, or in a temperature-controlled environment. That space costs your business money. If you have too much inventory, you may need satellite warehouses. Alternatively, you’re paying for empty shelves if you have more space than inventory.

Expired, dead, or obsolete stock also takes up space, so timely removal or disposal of this inventory is critical to opening up space for new or popular items. Logistics software can help reduce expired, dead or obsolete items on your shelves by ensuring proper put-away practices: new product placed behind older product, and moving old product to the front of the shelf so it is picked first.

Knowing what you have on hand at all times can help you optimize your space, improving the amount of money you spend on space requirements. With logistics management software, you’ll have up-to-date insight into the products on your shelves and the essential data associated with those products. Logistics technology can also help you plan accordingly for peak seasons providing historical data to manage space, restocking levels, and product demand to effectively meet the increase in demand.

Labor-related costs

We all know how frustrating it can be to dig through your junk drawer at home looking for the correct charger for your phone or the spare lightbulb for your holiday lights. Imagine that frustration on a larger scale, having to shift through boxes of inventory that may not be in the right place, are out-of-date, or not labeled correctly. This increases the likelihood for picking errors and takes time, and time is money.

Using logistics technology, warehouse operators can save time and reduce costs by providing employees with accurate information about where items are stored or if items are out-of-stock. Logistics management technology can also help warehouse managers create optimized walking paths for order picking, increasing employee productivity and reducing the time it takes to get an order out the door.

Supply chain management

It’s not surprising that the global pandemic highlighted inefficiencies and gaps in supply chains worldwide. Warehouses had a hard time keeping shelves stocked and meeting customer demand. In a 2020 IHL Group report the retail sector experienced severe global inventory distortion, with an estimated value for out-of-stock items at $1.14 trillion. However, over-ordering in preparation for future shortages can harm your business, resulting in the labor and space concerns outlined above, as well as causing frustration for employees trying to do their jobs, and for clients and customers who may see delays or errors in order fulfillment.

Logistics management technology helps businesses keep accurate records of the inventory on hand, determine replenishment levels, and place orders when stock reaches a certain point.

How to Improve Third-Party Logistics Management with Common Warehouse Best Practices

If you’ve experienced inefficiencies, cost overruns, or wrong order picking, your inventory logistics management processes and tools may be to blame. Improving standard warehouse practices, such as your putaway, picking, and return processes can make your operation more efficient and competitive, providing better service to your clients and customers.

Improve Putaway Processes

As we mentioned, space is a valuable thing in warehouse operations. Every square inch of space costs money, and maximizing how you use your space is critical. Improving your putaway processes can reduce congestion, errors, and product damage, speed up your picking processes, and improve warehouse safety.

With directed putaway processes, you and your employees know exactly where something should go, making it easier to find and retrieve it again. It’s more than approaching inventory putaway in a logical way; it’s about ensuring you have access to the best possible location every time you scan an item.

Improve Picking Practices

Properly managing inventory processes can also help in your picking practices. Knowing exactly where an item is in your warehouse can speed up the amount of time a worker needs to locate the item and improve batch picking processes, resulting in more accurate order fulfillment.

Combined with improved storage and putaway functions, logistics technology can create pick path optimizations allows you to find the most efficient paths possible, not necessarily the shortest, to get your orders to packing stations and out the door.

Improve Returns

Customers return items for many reasons. They may have received the wrong item, something was damaged, or they didn’t like the product once it arrived on their doorstep.

When working with returned items, workers need to ensure the item’s quality before returning it to inventory, that the item is not obsolete or expired, and enter the returned item into the book inventory at the right time. Handling returns is time-consuming and costs money, and it can be a significant source of inventory management problems. Logistics management technology can streamline your reverse logistics processes.

There is no better time to adopt logistics technology in your warehouse

Third-party logistics isn’t just some fancy term warehouse operators throw around to sound important. It has real effects on your bottom line. In fact, according to EasyPost data), companies can see a 25% increase in productivity, a 20% gain in usage space, and a 30% improvement in stock use efficiency with properly-implemented logistics management software.

FAQs

What is inventory logistics?

Inventory logistics is used to plan and control the storage of goods and materials and provides valuable information about the flow of these goods or materials through your warehouse.

How can logistics management software improve my warehouse costs?

Space, labor, and supply chain management are enormous costs for warehouse operators. Logistics technology can help you optimize your use of space and improve labor costs through efficient putaway, picking, and packing processes. It can ease the strain on the supply chain by providing accurate information about the products on your shelves.

How can logistics technology improve the visibility of my products?

Knowing what you have on hand at all times can help you maximize your space, improving the amount of money you spend on space requirements. With a warehouse management system, you’ll have up-to-date insight into the products on your shelves and the essential data associated with those products.

What other ways can logistics management software benefit my business?

Proper inventory logistics management can improve your business through better putaway practices (reducing congestion, errors, and product damage, speeding up your picking processes, and improving warehouse safety). Adopting best practices in inventory logistics improves the picking process by knowing where items are in your warehouse and optimizing the return process by validating the re-sale viability of a product before returning it to the shelf.

If you would like to learn more about how logistics management software can improve your warehouse operations, contact our sales team today or request a demo