Key Takeaways:

- SKU codes are unique alphanumeric identifiers used to distinguish one product variant from others in your warehouse, optimizing tracking and management.

- SKUs and UPCs are not the same; SKUs are specific to your company, while UPCs are universal and remain the same across all retailers.

- Proper use of SKUs improves accuracy in inventory management, enables inventory sharing across multiple channels, speeds up order picking, enhances packing and shipping processes, and improves customer service.

- SKUs help reduce backorders, incorrect orders, and shipping delays, enhancing overall customer satisfaction.

- Creating your own SKUs specific to your business needs can help avoid confusion and streamline operations. The use of a SKU generator can simplify this process.

The organization is an essential piece of inventory warehouse management. Your business can’t get very far if you don’t know what inventory you have. Defining SKU numbers is the very first step for a successful fulfillment business.

This is true whether you run an ecommerce shop, a warehouse, a brick-and-mortar store, or an omnichannel operation.

Here’s what we’re covering in our SKU guide to help you build a lean and profitable business:

What is an SKU Code?

SKU stands for Stock Keeping Unit. It’s an alphanumeric code between 8-12 characters that distinguishes one product variant from any others in your warehouse. This unique internal code allows retailers to keep track of their products.

The strength of an SKU lies in its uniqueness. Because it’s specific to your business, you can tailor the code to what customers or vendors ask most often about your product. Your customer’s needs and questions can help form your SKU designations.

This can include basic information, such as:

-

- Gender

- Brand

- Size

- Type

- Color

- And more

You can include whatever you find most important about your product in the SKU to differentiate it from the other inventory.

SKU vs. UPC: What’s the Difference?

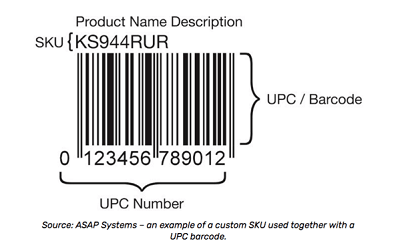

Many people use SKU and UPC codes interchangeably, but they serve two distinct purposes for retailers.

UPC stands for Universal Product Code. This is a 12-number code number given to the manufacturer and is more general than an SKU barcode. The Global Standards Organization issues UPCs. UPCs help companies identify the manufacturer of a product.

Basically, a UPC will always stay the same, while an SKU is specific to your company.

Larger companies sometimes opt to only use the UPC, but most companies find it useful to have both unique SKU and UPC. SKUs give more specific information about the product, while UPCs have more general information.

If something in a specific batch of products at the factory was compromised, for example, the UPC code is helpful to track down exactly where it went. However, an SKU can help determine where the product is within your inventory.

Top 7 Reasons Why You Need to Use SKUs

The logistics of retail can be tough. If incorrect or delayed orders plague your operations, your customer will seek out your competitors. Businesses must find any way to stand out from the competition. SKUs can give you the edge you need to be fast, efficient, and get a better understanding of your inventory and customer.

Here are just a few reasons why you should use SKUs in your warehouse inventory management software.

1.More Accurate Inventory Warehouse Management

Inventory is a tricky game. On one hand, overstocking on a product can seriously cut into profit because your carrying costs will increase. That’s capital you could’ve used on more popular products. However, going out of stock can mean a severe loss of potential business.

When you have a smaller amount of orders, it’s not as stressful to keep your inventory numbers updated in Excel and across your selling channels. However, there’s still more room for error since the data is being entered manually.

Each time a customer creates an order, and that order moves to the next step in your fulfillment process, you have to update your numbers. You don’t want a customer placing an order for inventory that appears in stock, but will actually have backorder status.

In order to execute lean operations without actually going out of stock, inventory needs to be as accurate as possible. Unique SKUs can help you know exactly what you have and let you know when the product needs to be reordered. You can get a real-time look at your inventory with incredible accuracy.

2. Inventory Sharing Across Multiple Channels

SKUs help you avoid overselling and keeping you from missing a sales opportunity across online stores and retail stores. With unique SKUs, you can share your inventory across all of your online stores, which means your available inventory will constantly be updated, in real-time. You can share your inventory across all sales channels(Retail stores, shopping carts, marketplaces etc), so there is no need to reserve inventory for just one. This means more sales opportunities for you, and more accuracy across all channels. It’s a win-win.

3. Faster and More Accurate Order Picking

Once your customer places an order, the shipment needs to go out quickly. In this Amazon era, customers have very little patience when it feels like their order is taking too long to be shipped. Many warehouses struggle to keep up with the pace of their customer expectations.

SKUs can help warehouses find what they need even more efficiently. They allow workers to find the exact product that they need with both speed and accuracy, which is required to keep up with customer demand.

As we mentioned, SKUs can be particularly helpful for products that have variants like color or size. For example, let’s say you have the same type of wrench, and you carry them in 15 different sizes. Looking for an SKU versus checking sizes will help your picker get that order to an order packing station faster. When you carry many variations of the same product, SKUs can help your pickers discern which is needed for an order faster.

Not only can they move faster, but the insight the SKUs give will help you to design a warehouse that is easier to navigate. You can put the best-selling items in the easiest-to-reach places and move slower inventory to the back. They can help you to identify where each item should go because you have a better understanding of what sells best.

4. Efficient Packing and Shipping

Not only will picking orders be easier, but the packing process is faster with SKU barcodes. Simply by scanning the barcode, you can automatically print out the order packing slip and shipment barcodes. This will create a more accurate inventory warehouse management and shipment, and a smoother process all around.

If a faster and easier packing and shipping process is something you want for your business, schedule a Logiwa demo today!

SKUs allow you to create a more digitized process with a warehouse or order fulfillment software to save time. When you scan the barcode to send off a shipment, your inventory numbers can be updated as well if you have an integrated system. Of course, you need to design, create barcodes by using a barcode generators app or a WMS warehouse software.

No more mistakes about products you didn’t know were sent out earlier in the day. You can get up-to-date inventory levels right away.

FREE DOWNLOAD: Ready to get started? Download our Excel SKU Template and start creating SKUs for your products today.

5. Accurate Cycle Counting

Some warehouses strive to keep as accurate inventory as possible with cycle counting. It’s less disruptive to daily operations and allows warehouse managers to ensure that they keep accurate inventory between scheduled full physical inventory counts.

SKU barcodes are essential to cycle counting. They directly affect the performance and accuracy of the counting process in your warehouse. The more thorough the SKU system, the faster and easier it is for cycle counting to take place.

6. Reduce Backorders, Incorrect Orders, and Shipping Delays

Have you ever walked into a shoe store and asked an associate for a specific size only to have them disappear for long amounts of time? Then they return to tell you that that specific size is out of stock?

It’s a frustrating experience for customers to wait around only to be told that the item they want isn’t there. SKUs help you to respond to your customer’s needs with speed and accuracy.

Through integration with point-of-sale systems, salesperson (whether B2C or B2B) can quickly respond to customer questions.

SKU barcodes won’t just help you respond quickly, but you’ll be able to minimize, and even potentially eliminate, your backorder situations.

These factors all result in increased customer satisfaction with your business. If there does come a time when you do have items that are out of stock, this underlying sense of brand loyalty will help you keep customers that you might otherwise lose to your competitor.

7. Better Suggestions for Your Customers

You can use SKUs to recognize product characteristics that help your sales team identify additional items that your customer might want. They could also suggest alternatives when what your customer wants isn’t available.

They can help give you valuable insight into the particular type of item that they want and help you quickly identify alternatives that will keep them happy.

This can also be done online too. Many online stores will offer suggestions for additional items that you might like, either as complementary to the item you’re looking at or as an alternative. This is typically done by applying an algorithm to the retailer’s SKUs to come up with similar items.

Following a search for a Nintendo Switch case, Amazon offered up sponsored suggestions for other Nintendo Switch cases (first row), but then also showed other related items (second row). This is the perfect opportunity to up-sell or cross-sell customers on items. Especially while they’re in a purchasing frame of mind.

How to Generate Your Own SKUs

Beware of using your supplier’s or wholesaler’s SKUs for your specific business. You could run into several problems using someone else’s SKUs.

First, it’s possible that there could be duplicate SKUs for different products. Because every vendor uses their own unique SKUs, duplicates can happen and cause serious confusion while trying to locate and sell products.

Second, every business has different customers, needs, and priorities. Your SKUs should reflect that. Keep in mind what’s most helpful to you and your company when deciding on how you’d like to create your own. Some general rules for correctly creating unique SKUs include:

-

- The first two-three numbers should be a top-level identifier (warehouse, supplier, etc.)

- In the U.S., most SKU’s are between 8-12 characters

- Make sure that each letter and number has a meaning

- Never use a zero

- End with sequential number series

- Make sure the format is easy to understand

These general guidelines will help keep your SKUs streamlined in your inventory and easier for everyone to understand.

Depending on how many products you have, generating unique SKUs for each product can become a cumbersome process. Many retailers avoid inventory warehouse management with SKUs because creating unique identifiers for each product is too challenging. It can waste precious time and resources that could be spent elsewhere.

A Pain-Free SKU Generator

When it comes to getting started, a stock-keeping unit generator can make all the difference to make the process as pain-free as possible.

That’s why we created an SKU number generator that makes creating a basic SKU code strategy easier. Our Excel spreadsheet can help you create an SKU code strategy quickly.

Download our free SKU generator and start your process to a more organized, efficient, and profitable business today!.

FAQs

What is an SKU in warehouse management?

An SKU, or Stock Keeping Unit, is an alphanumeric code that distinguishes one product variant from any others in a warehouse. This unique internal code allows businesses to keep track of their products.

How is an SKU different from a UPC?

An SKU is specific to your company and can include information relevant to your business or customers, while a UPC (Universal Product Code) is a 12-number code given to the manufacturer and is more general, serving to identify the manufacturer of a product.

What are the top benefits of using SKUs in inventory warehouse management?

Using SKUs in inventory warehouse management can make order picking faster and more accurate, streamline packing and shipping, improve inventory sharing across multiple channels, aid in cycle counting, and help reduce backorders, incorrect orders, and shipping delays.

How can I generate my own SKUs?

Creating your own SKUs involves deciding what information is most important to include about your product. This could be brand, size, color, and type. It’s important to make sure each letter and number in the SKU has a meaning, and to follow a consistent format that is easy to understand.

Where can I find the SKU number of a product in my warehouse?

The SKU number of a product should be clearly displayed on the product, typically on a label or barcode that can be easily scanned. The location may vary depending on your warehouse management system and product type.

What is the typical SKU format and how big is the SKU size?

SKUs are typically alphanumeric codes between 8-12 characters. Each character should represent something meaningful about the product such as brand, type, color or size.

How does SKU creation improve the efficiency of order picking in my warehouse?

SKUs can improve the efficiency of order picking by allowing warehouse workers to quickly identify and locate the exact product variant needed for an order. This is especially helpful for products with multiple variants.

How does having a unique SKU for each product affect inventory management?

Having a unique SKU for each product allows you to know exactly what you have in your inventory and when the product needs to be reordered. It enables real-time updates and improves the accuracy of inventory management.

What are the factors to consider while creating an SKU code for my products?

While creating an SKU code for your products, you should consider what information is most relevant to your business or customers. SKUs should be unique, consistent, and should avoid the use of zeros or special characters that could lead to confusion.

Can I use the SKU of my supplier or wholesaler for my business?

It’s generally not recommended to use the SKU of your supplier or wholesaler as this can lead to confusion and inaccuracies in your inventory management.

What are the potential issues of using supplier or wholesaler SKUs?

Using supplier or wholesaler SKUs can lead to potential issues such as duplicate SKUs for different products. Additionally, their SKUs may not reflect your business’s specific needs and priorities.

How does having SKUs improve the packing and shipping process in my warehouse?

SKUs can improve the packing and shipping process by enabling automated barcode scanning. This allows the quick printing of order packing slips and shipping barcodes, creating a more efficient and accurate process.

How can SKUs reduce backorders, incorrect orders, and shipping delays?

SKUs can reduce backorders, incorrect orders, and shipping delays by improving the accuracy and speed of inventory management and order fulfillment. With unique SKUs, you know exactly what’s in stock and can respond to customer’s needs swiftly and accurately.

How can SKU barcodes help in cycle counting in my warehouse?

SKU barcodes are essential to cycle counting, a method of keeping accurate inventory without disrupting daily operations. They make the counting process faster and easier.

How can SKU usage lead to better product suggestions for customers?

SKUs can aid in making better product suggestions to customers by identifying product characteristics. They can be used to suggest alternative or complementary products when a customer’s preferred item isn’t available.

What kind of SKU generator is best for creating a hassle-free SKU code strategy?

A good SKU generator should be able to create unique and meaningful SKUs that reflect your business’s needs and priorities. It should be user-friendly and capable of handling the quantity of products in your inventory.

Why should I avoid using a zero in my SKU numbers?

It’s recommended to avoid using zeros in SKUs because they can be easily overlooked or mistaken for other characters, leading to errors in inventory management.

How do SKUs enable efficient inventory sharing across multiple channels?

SKUs enable efficient inventory sharing across multiple channels by allowing real-time updates of available inventory. Unique SKUs can help you avoid overselling and ensure that your inventory is always accurate across all your sales channels.