The concept of supply chain sustainability has changed ecommerce operations. It’s influencing the choices of fulfillment networks, online sellers, and 3PLs by connecting profitability, environmental responsibility, and consumer trust.

But moving towards greener operations is about more than just biodegradable boxes and going paperless. It’s about energy efficiency, optimized labor, and reduced emissions. In this blog, we discuss how warehouse efficiency helps supply chain sustainability and the role of AI and automation.

Contents

Key Takeaways

- Sustainability is now essential for all ecommerce and fulfillment operations.

- Sustainable warehousing extends beyond traditional eco-centric initiatives to holistic approaches like boosting operational efficiency.

- Tracking energy, labor, and shipping efficiencies can save warehouse costs and reduce environmental impact.

- AI and automation boost warehouse efficiency and support eco-friendly inventory management and order fulfillment.

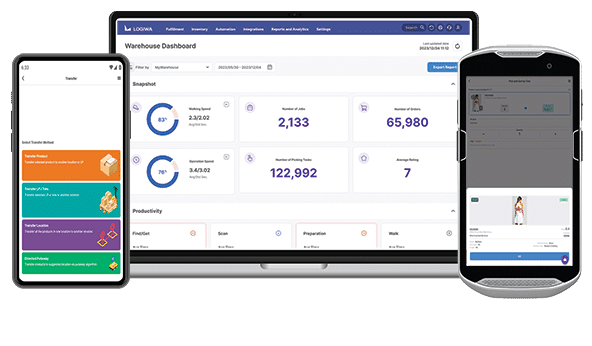

- WMS uses AI and automation to enhance sustainability by optimizing various processes.

The Importance of Moving Towards a Sustainable Supply Chain

Sustainable logistics are crucial for minimizing the environmental impact of mass production and global trade. It also helps build a positive brand image, foster customer loyalty, and attract environmentally conscious customers.

Sustainability is no longer limited to niche brands but is crucial for all ecommerce and fulfillment operations. Consider the supply chain sustainability insights aggregated by Zipdo:

- 57% of businesses are making sustainable business practices a current aim.

- 81% of CEOs worldwide view sustainability as key to business growth.

- 1/3 of consumers are choosing brands based on their social and environmental impact.

- 67% of multinational operations are turning to suppliers that will improve their environmental performance by 2025.

Sustainable warehousing signifies eco-consciousness and operational brilliance. Every shipped package represents a commitment to the planet and evolving consumer values. Beyond adopting eco-friendly practices, virtually every aspect of a business can contribute to becoming a green operation.

Measuring Supply Chain Sustainability in Your Warehouse

For warehouse operators, there are many pathways to sustainability. Exploring renewable energy, reducing packaging, and improving transportation are just a few examples.

To make your warehouse sustainable, you must focus on improving efficiency as well as adopting green practices. Every time you improve efficiency, you also reduce your carbon footprint.

Let’s discuss warehouse energy efficiency, labor efficiency and shipping efficiency to show how this is possible. Each has their own unique impact supporting a sustainable supply chain, and we can measure each like any other KPI.

- Energy efficiency is the cornerstone of a sustainable warehouse. By optimizing lighting, heating, cooling, and equipment usage, your warehouse can reduce its carbon footprint and energy consumption. Maximizing storage space can reduce energy usage and the need for additional warehouses. By implementing energy-efficient practices, you can save natural resources and reduce costs.

- Labor efficiency is about getting more done without requiring more resources. Advanced robotics and automation can boost your team’s speed and accuracy for maximum productivity. By combining humans and machines, you can do daily tasks faster and with fewer resources. Shipping more orders per carrier pickup minimizes energy consumption.

- Shipping efficiency involves minimizing packaging materials and reducing transportation emissions. By optimizing packing and shipping operations, you reduce waste and increase package capacity in trucks. Maximizing shipping space helps minimize the number of shipping vehicles and miles traveled for deliveries each day.

Warehouse efficiency and sustainability do not operate in isolation; they intertwine and reinforce each other. By monitoring energy, labor, and shipping KPIs, you can save money in your warehouse and help the environment.

Learn how to improve green efforts in Logiwa’s blog post, “How to Become a Sustainable Warehouse Operation.”

Harnessing AI and Automation to Achieve Supply Chain Sustainability

Let’s discuss the top way to achieve warehouse efficiency: AI and automation.

AI and automation make warehouses more efficient, especially for inventory management and fulfillment tasks.

Combining physical automation systems with facilitative automation brings sustainability to a new level. These examples show how a WMS uses AI and automation to make warehouses and supply chains more sustainable:

- Order routing. AI and automation help choose the optimal warehouse for order fulfillment to reduce emissions. This process ensures that fulfillment centers nearest to the consumer process orders and expedites order delivery.

- Non-wasteful inventory levels: AI and automation help predict demand and manage inventory levels efficiently. This not only prevents wasteful dead stock, but ensures your warehouse is not wasting energy by storing excessive amounts of inventory.

- Energy-saving stock allocation: AI and automation can ensure items are stored in the best warehouse locations. Directed putaway reduces deadstock and improves efficiency by streamlining receiving and picking. By strategically placing inventory based on demand and expiration date, you can protect stock and reduce energy waste.

- High-efficiency picking and packing: AI and automation work together to generate smart pick jobs. AI automation rules can prioritize orders based on details like item location, pickup time, and order details. This maximizes the number of orders fulfilled each day while reducing returns.

- Walking path optimization: AI and automation reduce motion waste by minimizing walking distances in the warehouse. AI can map the best routes for your workers using the information it has on your facility layout and orders. This ensures that we gather more orders in fewer trips, which leads to improved efficiency and energy conservation.

- Green shipping processes: AI and automation optimize packing by suggesting suitable boxes. With AI, you can streamline item staging to make the most of shipping space in vehicles. This reduces material waste and the total number of shipping trips.

With the right fulfillment management system, it’s easy to automate and integrate these AI-driven optimizations. Doing so decreases your environmental footprint while improving operational efficiency and customer satisfaction.

Learn how to revolutionize sustainability in our webinar with Prologis and Fulfillment IQ, “Greening Your Supply Chain – Harnessing WMS and AI for Smart Warehousing.”

Empowering Sustainable Warehousing with Innovative Fulfillment Technology

This blog explored sustainable warehousing, measuring it, and using technology for an eco-friendly approach.

Logiwa’s innovative fulfillment management solution enhances transparency, empowers sustainable practices and streamlines operational workflows. We use automation and AI to make warehouses more efficient and eco-friendly.

Logiwa is powering the next generation of competitive warehousing. Learn more by requesting a demo of our complete fulfillment solution.

FAQs Related to Running a Sustainable Warehouse

How do AI and automation contribute to supply chain sustainability?

AI and automation optimize processes in a sustainable warehouse. AI predicts demand and improves warehouse processes to reduce excess inventory and energy usage. Automation helps streamline inventory management and shipping processes, reducing waste and fuel usage. AI-driven order routing reduces transportation emissions.

What are the best ways to measure sustainability in a green warehouse?

You can measure warehouse sustainability using metrics related to labor, operations, shipping, energy, and cost-savings.

What role does warehouse management play in supply chain sustainability?

Sustainable warehouses use eco-friendly practices, such as smart inventory management and green shipping methods. This reduces energy consumption, minimizes waste, and enhances overall operational efficiency. Sustainable warehouses contribute significantly to achieving a green and responsible supply chain.

Optimize multi-warehouse and multi-client operations at both the macro and micro levels

Warehouse Management

Modern digital WMS powers a modern fulfillment experience