In fact, warehouses with automation systems are 36% more likely to experience reduced labor costs and 76% more likely to have enhanced inventory accuracy. However, you’ll only experience these and other benefits if you implement the right warehouse automation system.

In this guide, you’ll learn the basics of warehouse automation and discover the eight best warehouse automation systems on the market today. But first, here are the key takeaways from our warehouse automation solutions guide:

- Warehouse automation systems automate the processing and movement of inventory into, within, and out of warehouses.

- Warehouse automation can enhance warehouse safety, productivity, cost-efficiency, and space utilization.

- Automated systems generate valuable data regarding warehouse operations, and you can leverage the insights to improve your warehouse processes.

- Pick the best warehouse automation system for your facility by considering each platform’s price, features, scalability, and user-friendliness.

- Logiwa, the leading warehouse automation system, supports several physical and facilitative automation systems out of the box.

Contents

What Are Warehouse Automation Systems?

Warehouse automation systems are solutions that automate the processing and movement of inventory into, within, and out of warehouses. The technology helps you execute, streamline, and optimize warehouse operations with minimal human intervention.

Warehouse automation systems can be hardware or software solutions. Hardware solutions include transportation, conveyor, and robotic systems for storing, sorting, picking, packing, and moving inventory. On the other hand, software solutions include warehouse management systems and inventory management systems that coordinate automated warehouse processes.

The Benefits of Warehouse Automation Systems

Below are some of the benefits you can experience after implementing warehouse automation systems.

- Improved efficiency: Automating tasks like picking, packing, shipping, and storage can speed up warehouse operations, leading to increased productivity. Also, automating repetitive tasks, such as order receiving and labeling, can prevent errors and improve order fulfillment accuracy. Faster and more accurate order fulfillment will enhance customer satisfaction, improving your brand image and attractiveness.

- Reduced labor costs: Automation can reduce your reliance on human labor to complete repetitive and physically demanding tasks. Since labor takes up a high percentage of the cost of running a warehouse, minimizing labor costs with automation can significantly boost your profitability.

- Optimized space utilization: Automated systems can help make better use of your storage space. For example, a warehouse management system can help you plan inventory storage so you don’t waste space, misplace inventory, or store goods inefficiently. The system also keeps you updated about the location of every inventory to simplify retrieval.

- Real-time inventory tracking: Warehouse automation systems, such as inventory management systems and automated storage and retrieval systems, can provide real-time visibility into inventory levels. It ensures you know how much inventory you have and forecasts demand to help you avoid costly overstocking or understocking.

- Enhanced safety: Automated robotic systems reduce reliance on human labor to perform dangerous tasks, such as moving heavy loads. Keeping human workers out of harm’s way will make your warehouse safer and prevent downtime caused by accidents.

- Data and analytics: Automated systems generate valuable data regarding your warehouse operations. Analyzing this data will provide valuable insights into underperforming aspects of your warehouse. You can leverage such insights to improve your warehouse operations.

Types of Warehouse Automation

Warehouse automation can fall under physical or facilitative automation. Let’s dive into each.

Physical Automation

Physical automation involves using hardware such as automated machinery to perform warehouse processes. It substitutes or replaces manual labor by performing storing, sorting, picking, packing, and other inventory and order fulfillment tasks. Some common examples of physical automation systems include:

- Automated Storage and Retrieval Systems (AS/RS): AS/RS systems store and retrieve inventory with robotic cranes or shuttles.

- Conveyor systems: Conveyor systems are immobile systems that automate inventory movement within a facility.

- Robotic picking systems: Robotic picking systems feature mechanical arms for picking and sorting items.

- AGVs (Automated Guided Vehicles): AGVs are mobile robots that transport goods within a warehouse along predefined paths. Alternatively, you can opt for Autonomous Maneuverable Robots (AMRs), or mobile robots that navigate warehouses on their own, without predefined paths.

Facilitative Automation

Most facilitative automation involves using software to automate workflows by setting automation rules with the help of algorithms. Such automation systems help optimize warehouse processes, maximize resources, and minimize errors. Examples of facilitative automation systems include:

- Warehouse Management Systems (WMS): A WMS application provides a central control unit for monitoring, managing, and monitoring all your warehouse operations. Warehouse operations you can control and automate with a WMS include inventory management, order processing, task allocation, and shipping.

- Order Management Systems (OMS): OMS software manages and optimizes order fulfillment processes, such as inventory allocation, picking, packing, labeling, and delivery scheduling.

- Inventory control software: The primary function of inventory control software is the automation of inventory storage, tracking, and management. It optimizes storage, keeps you updated about inventory levels and location, and facilitates efficient stock replenishment.

How to Evaluate Warehouse Automation Systems

Since warehouse automation systems are not equal, pick the best one for your needs by considering these factors.

Price

Warehouse automation systems are available at different price points, and you should pick a solution with a price plan that fits your budget. However, the most affordable product may not be right for you because it lacks the features you require. So, instead of prioritizing affordability, compare automation solutions and pick the one that fits your warehouse needs.

Features

Choose a warehouse automation solution with features that simplify optimizing your warehouse, such as easy integration, hassle-free automation implementation, and more. The solution should support your preferred number of users and fit your warehouse ecosystem. Also, select a user-friendly solution that you can implement quickly to shorten your time to value.

Scalability

Your warehouse automation system should be able to easily scale to meet your needs as your company and customer base grow. A system with poor scalability can cause downtime, bottlenecks, and inefficiencies when your needs exceed its capabilities.

Unlock a personalized tour of Logiwa IO

Comparison of 8 Best Warehouse Automation Systems

| Key Features | Integrations | Hosting | Use Case | |

| Logiwa |

|

|

|

|

| Softeon |

|

|

|

|

| Fortna |

|

|

|

|

| Symbotic |

|

|

|

|

| Swisslog |

|

|

|

|

| Omron |

|

|

|

|

| Dematic |

|

|

|

|

| Locus Robotics |

|

|

|

|

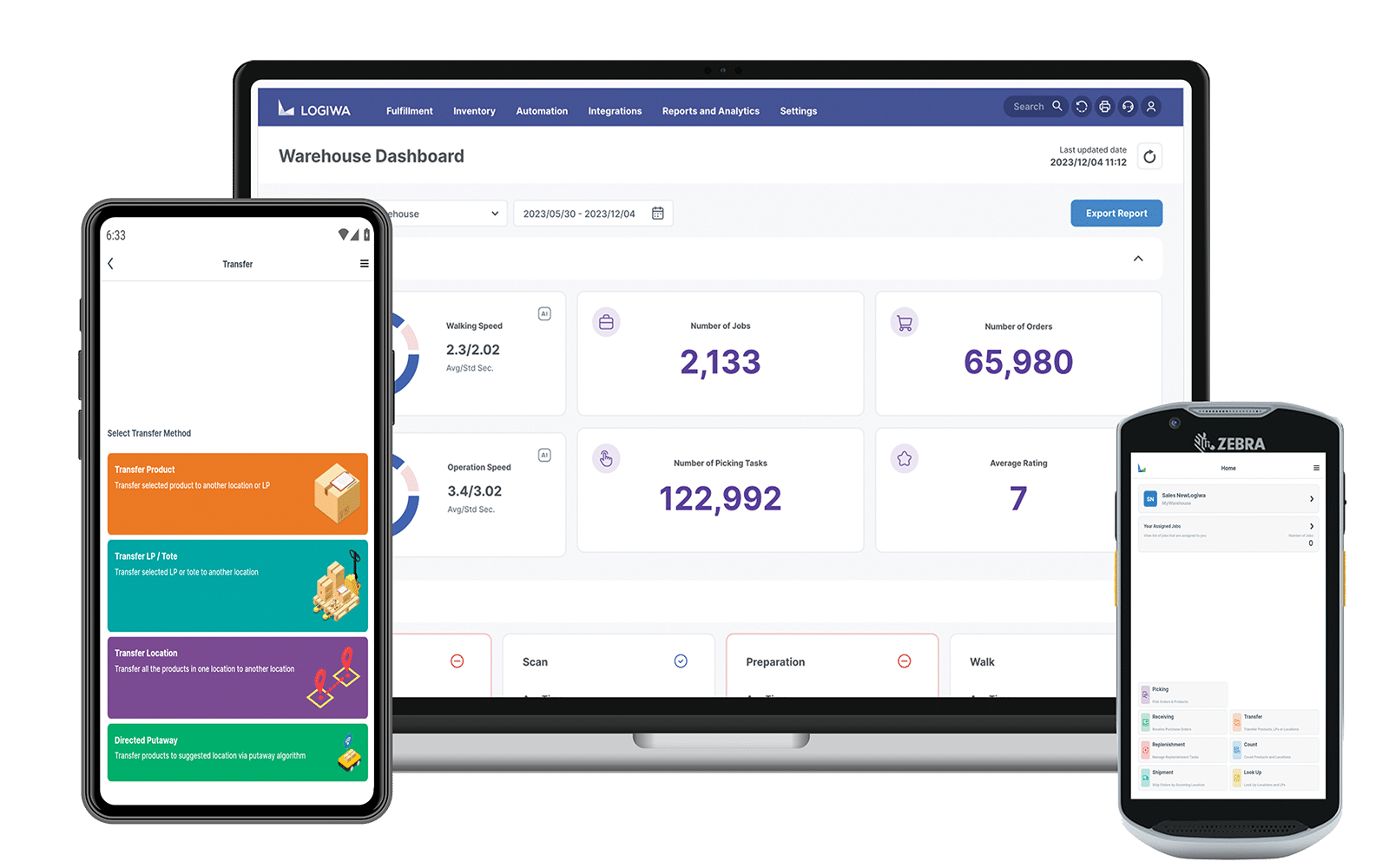

1. Logiwa

Rating: 4.2/5 (G2)

Key Features:

- Real-time inventory visibility and control

- Free robotics connectors

- Storage optimization

- Smart automation

- Scalable and adaptable

- Up to 100% uptime

Logiwa is a cloud-native warehouse management system suitable for facilities with low or high order volume. The WMS comes packed with a host of features, including several warehouse automation options.

For instance, it offers various automation protocols for streamlining and optimizing storage, picking, packing, documentation, and more. Many Logiwa users are saving hours per day by implementing even the simplest automation rules.

It also comes pre-integrated with leading fulfillment partners, including robotic system integrations that let you control and monitor your warehouse robotic systems from the application. Even if Logiwa doesn’t have your desired integration, you can easily connect your platforms or apps with the system’s API/EDI functionality.

Since Logiwa is user-friendly and highly configurable, onboarding is fast, reducing your time to value. Its scalability also ensures that the platform can adapt to your needs as your company grows or during peak periods.

Thanks to our cloud-native design and mobile app, you can use Logiwa to monitor and manage your warehouse automation remotely. If you want a competitively-priced WMS that doesn’t compromise on value, Logiwa checks that box too with its reduced professional service fees.

2. Softeon

Rating: 3.5/5 (G2)

Key Features:

- Labor, transportation, and order management

- Highly configurable

- Slotting optimization

- Billing management

You can get Softeon as a WMS with warehouse execution system (WES) capabilities or a WES that you can integrate with your existing WMS to automate your warehouse. Softeon’s WES software offers several automation opportunities, including options to automate picking, order batching, resource allocation, billing, and replenishment.

The system also provides real-time visibility into throughput, bottlenecks, and other events so you always know what’s happening in your warehouse. Depending on your needs, you can get Softeon as a cloud, on-premise, or hybrid solution.

The cloud solution offers superior scalability and versatility, while the on-premise solution offers better security and control. The hybrid solution, on the other hand, offers the best of both worlds.

3. Fortna

Rating: 3.0/5 (Capterra)

Key Features:

- Robotics and equipment integration

- 24/7 customer support

- Intuitive web-based user interface

- Real-time control of material-handling equipment

The Fortna WES allows you to leverage the cloud to monitor and control your warehouse processes remotely. The intelligent warehouse software provides options to optimize order fulfillment processes through automation.

For example, you can integrate the WES with AGVs, AMRS, AS/RS, conveyor systems, and other warehouse robots. Once integrated, you can leverage the connected hardware to automate tasks and boost productivity.

Besides automating machines, you can optimize your labor force with Fortna by automating task assignments, picking paths, and more. The system’s science-backed proprietary algorithms ensure improved operational performance to help you save money and improve warehouse efficiency.

4. Symbotic

Rating: No rating available

Key Features:

- Automation hardware and software

- Fully scalable

- Smart tasking, routing, and palletization algorithms

- Advanced mobile robotics controls

Symbotic is an end-to-end solution for automating your entire warehouse. It offers automation hardware, such as autonomous mobile robots and robotic arms for picking, transporting, and palletizing inventory efficiently. You can control every physical automation with Symbotic’s AI-powered software, which can manage hundreds of warehouse robots at once.

If you already have warehouse robots, you can use the Symbotic AI-powered WMS to control them or get just the robots if you already have a comprehensive WMS. You can use Symbotic’s hardware and software with other systems because they seamlessly integrate with a wide variety of warehouse solutions.

5. Swisslog

Rating: 4.5/5 (Capterra)

Key Features:

- Modular WMS

- WES, WMS, WCS, and ACS functionality

- Cloud-based services

- Business Intelligence tools with simple dashboards

- 24/7 support

Swisslog offers data-driven solutions to automate warehouse and logistics processes. Swisslog’s SynQ WMS integrates with warehouse machines and leverages data to create and implement automation protocols.

Swisslog also connects clients with physical automation suppliers that provide everything from AGVs and conveyor systems to picking and palletizing solutions. You can integrate these systems with the SynQ WMS to monitor and control automated operations in real-time.

In summary, Swisslog can be your all-in-one solution for implementing warehouse automation to reduce overheads and boost performance.

6. Omron

Rating: No rating available

Key Features:

- Ethernet-based machine control network

- All-in-one system for machine and process control

- Open communication and programming standards

- Synchronous machine control

Omron provides on-premise warehouse automation solutions to keep you running smoothly and more efficiently. Its Sysmac Platform synchronizes automated machines to boost database connectivity and ensure seamless execution of picking, packing, storage, and more.

You can also rely on Omron’s warehouse management and control systems to optimize logistics, inventory management, and customer communications. The solution is suitable for various industries, including retail and manufacturing, and you can adapt it to meet your needs and warehouse goals.

7. Dematic

Rating: 4.8/5 (G2)

Key Features:

- 24/7 customer support

- Seamless implementation

- AI-powered

- Real-time data insights

Dematic leverages artificial intelligence and real-time data to execute and optimize warehouse automation. Automate your physical processes with Dematic hardware, such as its receiving, transport, picking, and storage systems. Dematic also offers software for facilitating warehouse automation and controlling automated robots.

Software options include Dematic Operate for monitoring and controlling single-site operations and Dematic Connect for multi-site automation. Get full visibility of your warehouse by integrating Dematic hardware and software with your existing WMS.

The system seamlessly integrates with various leading warehouse management solutions, including Logiwa, which provides one-click integration.

8. Locus Robotics

Rating: No rating available

Key Features:

- Multi-language display

- Flexible configuration

- Easily scalable and integrated

- Robots as a Service (RaaS) option

Locus Robotics is known for its automated mobile robots and other physical automation products. The company also provides LocusONE, a warehouse automation platform powered by data science. The system provides an all-in-one solution for programming, deploying, and monitoring fleets of automated warehouse robots.

Since deploying warehouse robots can be expensive, Locus Robotics offers clients Robots as a Service (RaaS) as an alternative. It’s a subscription-based program that reduces the operational costs and technology barriers typically associated with deploying automated solutions.

Another upside of Locus Robotics systems is you can integrate them with other solutions, including warehouse management systems like Logiwa. The integration connects automated systems, providing you with more data to optimize your warehouse operation efficiency.

Automate Your Warehouse Processes With Logiwa WMS

Unlike the other warehouse automation systems we discussed, Logiwa provides a comprehensive WMS for managing and automating all your warehouse equipment and processes. You can easily connect it to your automated systems to control them and get real-time insights.

You can also use the WMS to automate various administrative processes, such as billing, task assignment, rate shopping, label printing, and more. Logiwa is competitively priced, highly scalable, and flexible enough to work in any warehouse.

Request a free demo today to experience the many benefits of choosing Logiwa to automate your warehouse operations.

Warehouse Automation System FAQs

Q: What are warehouse automation systems?

A: Warehouse automation systems are solutions that automate the processing and movement of inventory into, within, and out of warehouses. They help streamline and optimize warehouse operations with minimal human intervention. These systems can be both hardware solutions, like transportation and robotic systems, or software solutions, such as warehouse management systems.

Q: Why should businesses consider implementing warehouse automation systems?

A: Implementing warehouse automation systems can lead to improved efficiency, reduced labor costs, optimized space utilization, real-time inventory tracking, enhanced safety, and valuable data analytics. These benefits can result in faster and more accurate order fulfillment, boosting customer satisfaction and overall profitability.

Q: What types of warehouse automation systems are available?

A: Warehouse automation can be categorized into physical and facilitative automation. Physical automation involves hardware like automated machinery for tasks such as storing, sorting, and picking. Examples include Automated Storage and Retrieval Systems (AS/RS), conveyor systems, and robotic picking systems. Facilitative automation primarily uses software to automate workflows, such as Warehouse Management Systems (WMS) and Order Management Systems (OMS).

Q: How do warehouse automation systems enhance safety?

A: Automated robotic systems reduce the need for human labor to perform potentially dangerous tasks, such as moving heavy loads. This minimizes the risk of accidents, making warehouses safer and preventing downtime caused by injuries.

Q: How can businesses evaluate the right warehouse automation system for their needs?

A: Businesses should consider factors like price, features, scalability, and user-friendliness. It’s essential to choose a system that fits the warehouse’s specific needs, integrates well with existing systems, and can scale as the business grows.

Q: Why is Logiwa considered a leading warehouse automation system?

A: Logiwa is a cloud-native warehouse management system that offers real-time inventory visibility, storage optimization, smart automation, and scalability. It supports several physical and facilitative automation systems and has hundreds of pre-built integrations. Its user-friendly design ensures quick onboarding, and its competitive pricing offers value for money.

Q: What is the Robots as a Service (RaaS) option provided by Locus Robotics?

A: Robots as a Service (RaaS) is a subscription-based program offered by Locus Robotics. It reduces the operational costs and technology barriers typically associated with deploying automated solutions, making it more accessible for businesses to implement automation.

Q: How do warehouse automation systems contribute to cost efficiency?

A: Warehouse automation systems can reduce labor costs by minimizing the reliance on human labor for repetitive and physically demanding tasks. They also optimize space utilization and improve inventory management, leading to cost savings.

Q: Can warehouse automation systems integrate with other business systems?

A: Yes, many warehouse automation systems can seamlessly integrate with existing business systems, such as Warehouse Management Systems (WMS) or Enterprise Resource Planning (ERP) systems. This integration provides a unified platform for managing and optimizing warehouse operations.

Run a fully digital warehouse with mobile apps, smart job batching, automation rules and robotics integrations

Warehouse Management

Modern digital WMS powers a modern fulfillment experience