With warehouse operations, there’s a constant need to assess where you can streamline processes and reduce costs. One way to improve warehouse inefficiency is to reduce the number of manual tasks you must complete each day. Luckily, this is possible through the help of WMS robotics.

In this guide, we’ll define WMS robotics, discuss how they interact with warehouse management software, and how you can get started.

Contents

What Is Robotics?

The term “robotics” refers to the science behind machines that perform tasks that are otherwise risky, time-consuming, or impossible for humans. As for warehouse robotics, this subset refers to the automated systems, machines, and software that perform tasks such as transporting material, picking and packing, gathering and analyzing order data, and more.

What Is Warehouse Management Software?

Warehouse management systems (WMS), also known as WMS software, are platforms that manage and streamline specific warehouse processes, from inventory control to picking and packing.

As an example, WMS software can manage order fulfillment by tracking sales and orders while also organizing carriers and shipping routes.

WMS Robotics: Why Combine Your WMS With Robots?

Combining robotics with WMS software can help you solve common inefficiencies within your warehouse and reduce costs.

For example, WMS robotics can eliminate manual tasks that often result in human errors that damage profits. Plus, robotics allow you to scale or reduce operations quickly based on demand. This means you can increase output when needed without sacrificing quality and decrease to reduce overhead costs.

In addition, automating your warehouse operations using WMS robotics will help you provide a better customer experience due to increased processing and delivery speeds.

Want to learn more about AI in your warehouse? Download our free guide, Critical Role of AI in Warehouse Operations today.

How to Get Started With WMS Robotics

To get started with WMS robotics, you’ll need to assess your warehouse needs, select the right provider, and create a strategy for implementation. Let’s dive in.

#1. Assess Your Warehouse Needs

The first step is to assess where you require robotics support in your warehouse. Start by answering this question: Which processes or tasks within your warehouse could benefit the most from automation?

For example, is order picking resulting in a bottleneck in your current process? There’s a robot for that. Automation exists for a variety of other tasks as well, including lifting heavy objects, storing inventory, replenishing products, and more.

#2. Choose the Right WMS Robotics Provider

Once you have assessed where robots can be implemented, it’s time to select a robotics provider. Your best bet is to choose a provider that specializes in WMS robotics and that integrates with your current WMS software and other tools.

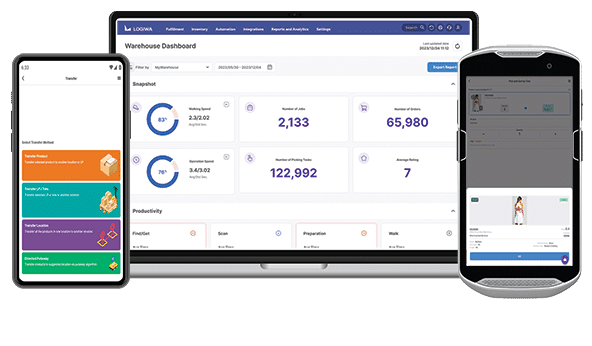

Logiwa offers a complete WMS solution that integrates seamlessly with leading providers, including Locus Robotics, Dematic Robotics, and 6 River Robotics. Through these integrations, you can take advantage of machines such as AMRs, picking bots, drones, and more.

In addition to robotics, we also offer pre-built integrations for most ecommerce, shipping, and accounting apps and services. With Logiwa, you have everything you need to get started with incorporating WMS robotics into your current tech stack.

#3. Implement WMS Robotics

With a partner selected, the last step is to implement WMS robotics within your warehouse. There are various steps involved in implementation, and your robotics partner should support you through each.

The implementation steps include:

- Ensuring you have clear plans for how you will use warehouse robots.

- Planning necessary warehouse infrastructure adjustments to make room for robotics.

- Coordinating with your provider to prepare your team for automation.

- Integrating your current apps and services to fully incorporate and use robotics.

- Setting up and testing all robotic systems to ensure they work as planned.

Best Practices for Managing WMS Robotics

As you implement and manage WMS robotics within your warehouse, there are a few best practices to follow:

- Create a dedicated WMS robotics team: Every new software implementation needs a champion to ensure you follow processes and meet your goals. Select a dedicated WMS robotics team that will head up your implementation and work hand in hand with your robotics provider.

- Incorporate WMS robotics slowly: Work doesn’t stop for the warehouse. Even during implementation, your customers will still expect their orders. Incorporating WMS robotics slowly over time will enable you to continue fulfillment processes without costly downtime.

- Onboard and train warehouse workers on robotics technology: Those that will work alongside the robots daily must understand how to use them properly. Take adequate time with the support of your robotics provider to onboard and train warehouse workers during the implementation process.

- Monitor and evaluate the success of all automation: After implementation, continuously monitor and evaluate your WMS robotics. This will ensure you’re able to make necessary adjustments to boost efficiency and make the most of your investment.

Overcoming Common Challenges

The field of robotics is ever-evolving. This means there will be challenges along the way. Luckily, these challenges are easy to overcome with a bit of planning and expert advice. Let’s discuss some issues you may experience and how you can solve them.

- Poor implementation: Take time to develop an implementation strategy complete with goals to use as a roadmap. Be sure to follow the steps and best practices discussed above.

- Slow scalability: When planning your robotics implementation, work with your provider to determine the steps necessary to scale robotics across your warehouse.

- Worker and robotics collaboration: Support your workers in learning how to use WMS robotics safely and effectively by offering training. Your team will be more likely to collaborate with robotic tools if they understand their benefit and how to use them.

Implement Warehouse Robotics With Logiwa

Implementing warehouse robotics can be a challenge. However, Logiwa can help. Logiwa is a leading provider in WMS robotics, offering robust WMS software and integrations with state-of-the-art robotics companies. To see how WMS robotics can benefit your warehouse, book a demo of Logiwa today.

Scale up B2C fulfillment operations with an integrated digital warehouse and fulfillment system

Warehouse Management

Modern digital WMS powers a modern fulfillment experience