Order Picking Automation Rules

Save time with scheduled picking jobs and advanced automation rules

Logiwa’s Digital Warehousing module is powered by the most advanced and flexible automation rules in the market. We have default automation rules that streamline everything from inbound operations and order routing to your pickers’ walking-path and DTC packing and shipping processes.

With Logiwa’s advanced order picking automation rules you can give pickers proactive directions that guide them to the closest location in their job list. Guided picking trips improve picking time by 30% – which means more orders can be fulfilled each day with the same headcount.

Logiwa’s algorithms can be used out of the box or modified based on your specific business or location requirements. You can also create new custom automation rules to turbo-boost your warehouse productivity even further.

Our order picking automation and other automation rules increase warehouse productivity with:

- Directed putaway algorithms

- Smart picking jobs

- Scheduled picking jobs

- Walking path optimization

- Order routing

- Location-based rules

- Zone-based rules

- Fixed and dynamic picking locations

- Identical item order picking

- Single SKU order picking

- Multi SKU order picking

- Oversized item order picking

- Fragile item order picking

- Store based picking

- Carrier based picking

- Customer based picking

- Replenishment algorithms

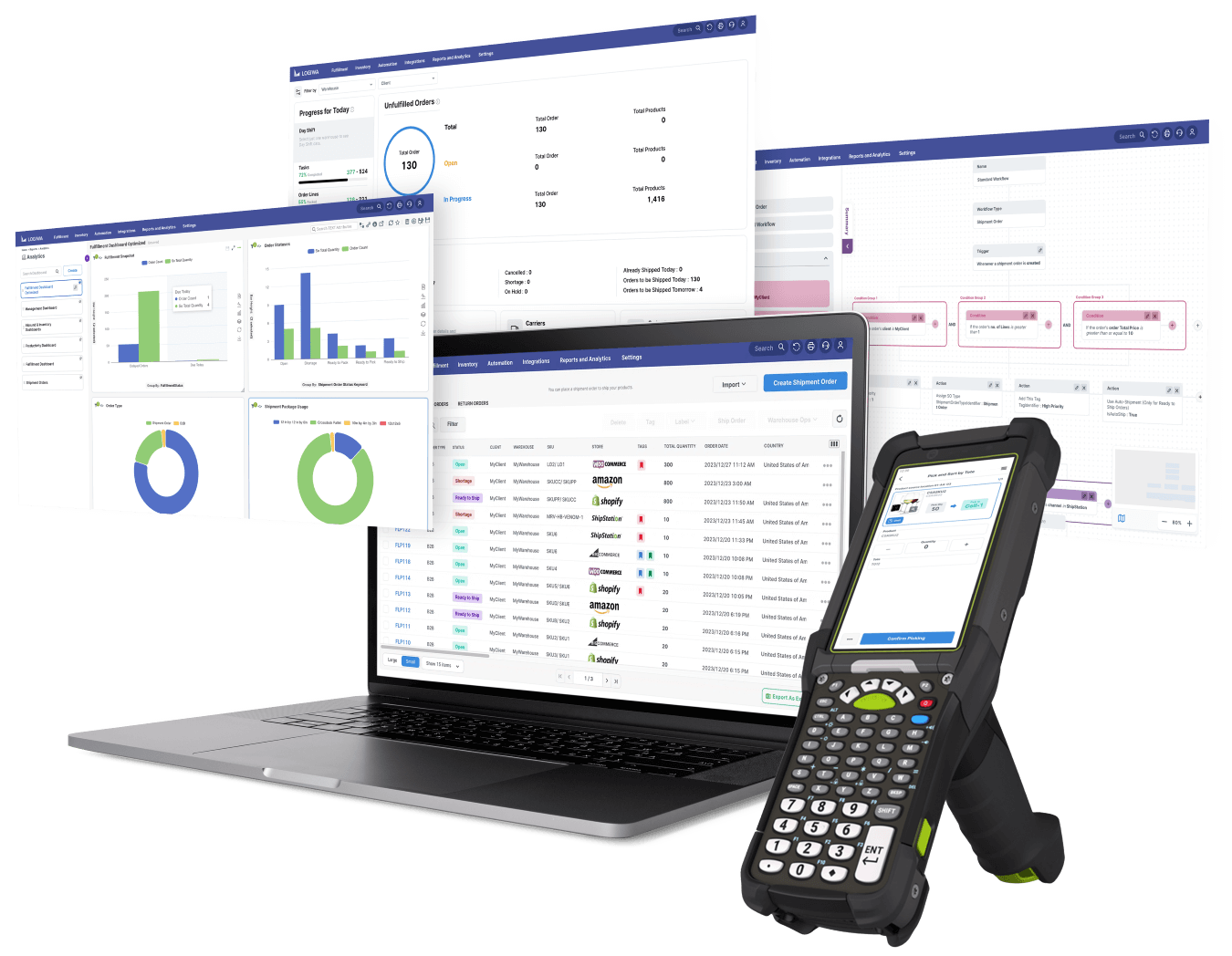

Everything brands, online sellers and 3PLs need to achieve high-volume fulfillment success

Check out all the functionality we provide and then just imagine all of this power running in your fully digital warehouses and across your integrated fulfillment network. Serious results.

- Receiving

- Directed putaway

- Picking and packing

- PICK-FACE replenishment

- Return management

- Cycle counting

- Inventory transfers

- Multi-warehouse operations

- Multi-client operations

- Shipment rule automation

- DTC packing station

- Kitting and bundling

- Scale integrations

- Order routing

- Putaway automation rules

- Inventory allocation automation rules

- Automate picking job creation

- Shipment box suggestions

- Walking path optimization

- Put-to-wall

- Robotics integration

Logiwa makes a fast impact on your business

40%

increase in labor efficiency

3x

more orders shipped after first three months on Logiwa

8%

lower shipping costs with Logiwa rate shopping

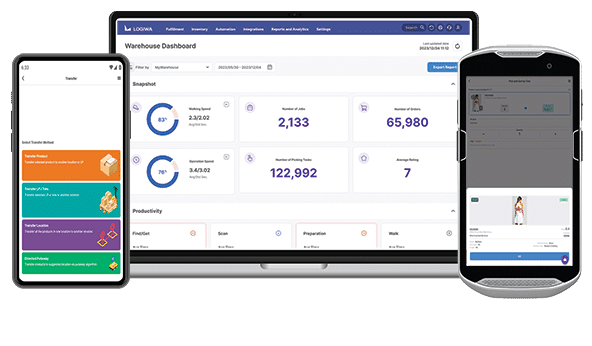

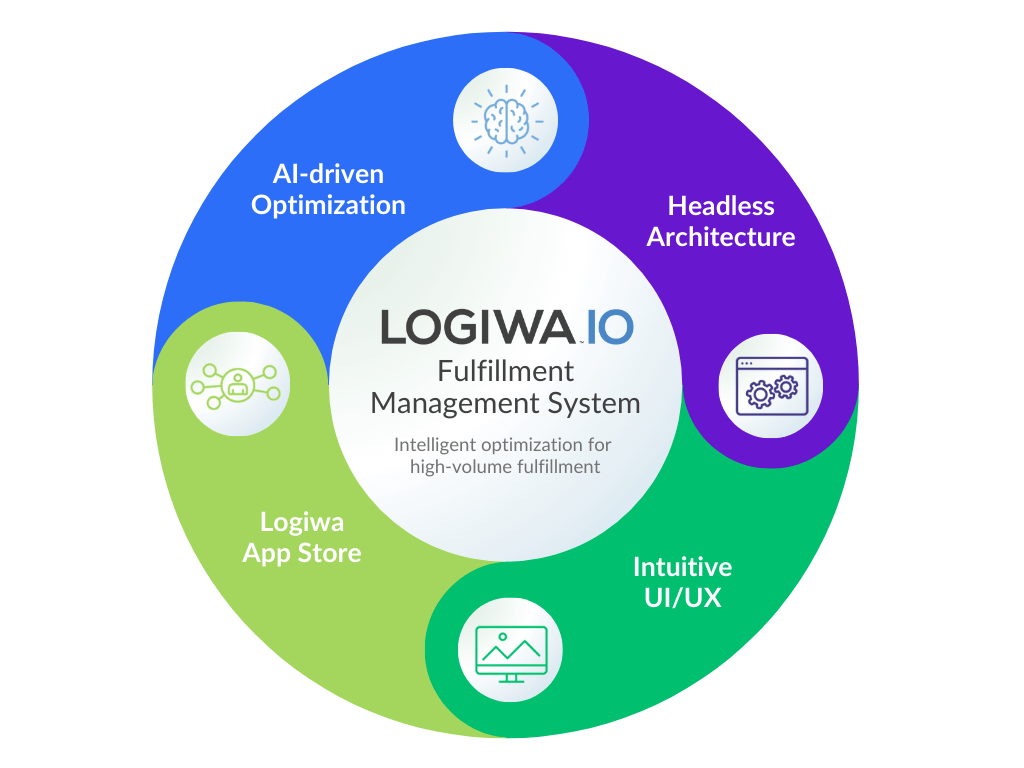

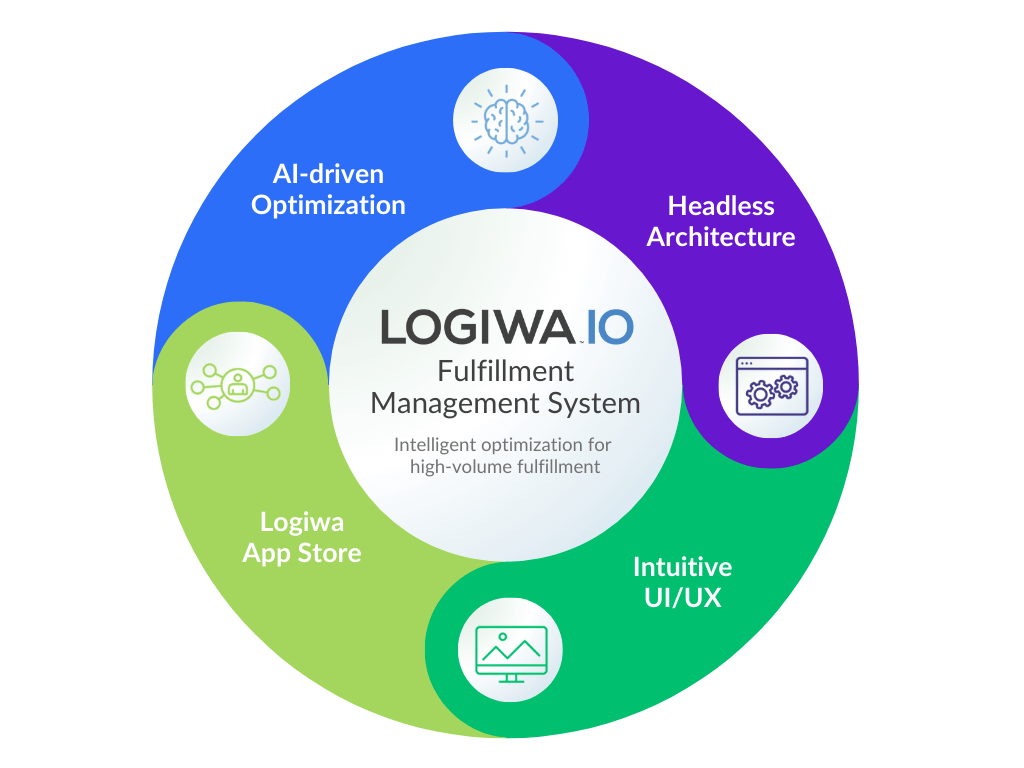

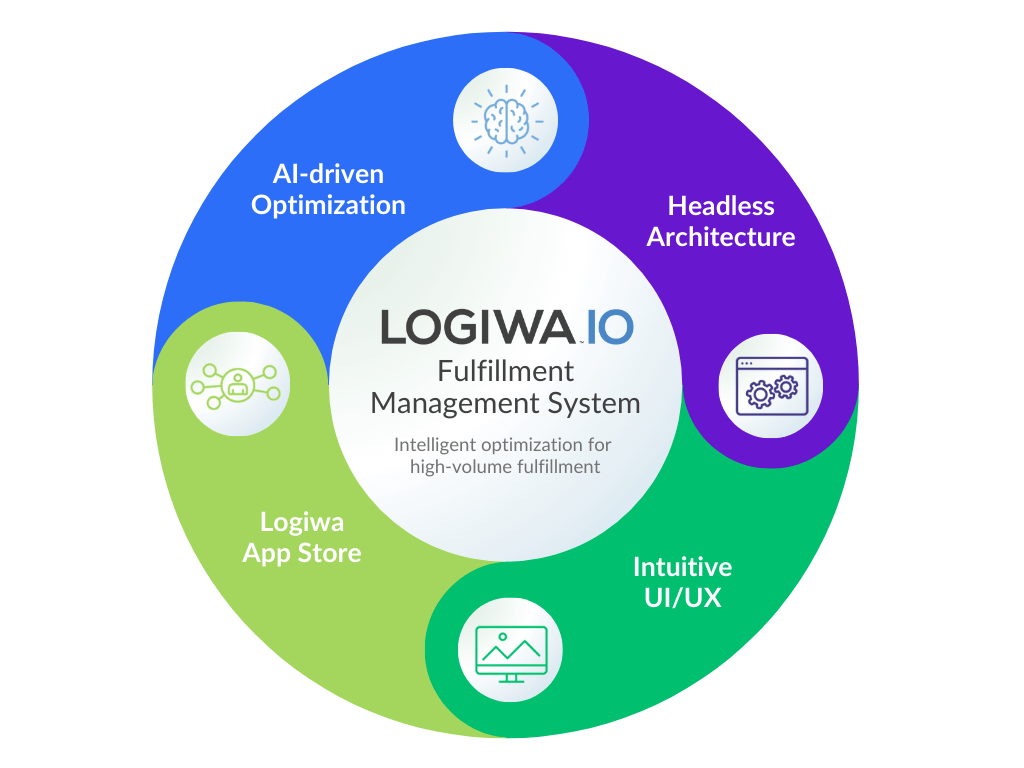

Go beyond legacy WMS with Logiwa IO

When it comes to meeting modern demand, traditional warehouse management systems can’t keep up. Logiwa’s all-in-one FMS offers an agile, scalable solution to meet your changing business needs.

AI-driven Optimization

Streamline operations with waves and jobs for enhanced outbound flow. Monitor on-ground activities to optimize workforce management with labor standards.

Headless Architecture

Groundbreaking headless, versionless, and serverless architecture. Seamlessly adapt your operations to changing needs, design your own add-ons, and scale effortlessly.

Intuitive UI/UX

Ensures an engaging user experience with an intuitive app design. Onboard new employees in hours, not days.

Logiwa Marketplace

Our partner ecosystem allows you to add features and modules—your own, and those from the marketplace—for limitless configurability and continuous innovation.

Customer Success

See what our customers say

FAQs about Order Picking Automation Rules

What is order picking system?

How does the order picking automation work?